The QASS machine-learning kit -

ideally prepared for research, development

and industrial use

The construction kit

- The measuring cube „Optimizer4D“, a compact high-performance PC with Linux as an operating system, and everything you need for industrial machine-learning implementations.

- QASS structure-borne sound can extract big data from almost any manufacturing process and use it for process analysis and optimisation.

- Open communication modules for the integration of all conceivable data sources and correlation with high-speed measurement data.

- QASS open-source modules integrate the "Optimizer4D" into the network and into machine-learning development environments such as Jupyter Lab.

To make it as easy as possible for you to get started, we cover 50% of the price for universities.

If you are not yet familiar with QASS, you can find a list of selected customers, universities and institutesthat use our system

and here you can find our

QASS-Measuring-Cube

Machine Learning

We develop the data analyses in the Jupyter Lab, script the measurement sequences and analyze the data with Tensorflow oder PyTorch. We transfer models and real-time-capable data analyses and machine learning models directly into the analysis operators of Optimizer4D and apply them directly to the machine in real-time operation. The results can be easily transferred to real production environments.

Big Data

With our structure-borne sound sensors, 25 MSamples/s in 16 bit resolution can be recorded in almost all manufacturing processes. With our magnetic sensors, we evaluate 4 MSamples/s in 24-bit resolution to assess the hardness and other properties of ferromagnetic components.

Sensor fusion

Sensors that supply data via USB or Ethernet can be connected to our Optimizer4D and correlated with our high-speed sensors.

Visualization of measurement data

The measuring devices are currently equipped with flash memory from 2 TB to 16 TB. Data rates of over 100 MB/s can be recorded continuously.

On the subject

Models and real time

The development of our machine learning (ML) and analysis models usually takes place in the form of a prototype in Jupyter Notebooks. The advantage of Jupyter Notebooks is that they enable highly interactive and therefore agile development.

Network

All data can be stored in parallel on the network. Each

Optimizer4D can be operated completely remotely from a browser.

Compression

All data streams can be compressed and pre-processed on the measuring computer. Logs and results are stored in SQL databases and can be correlated with the raw and compressed data.

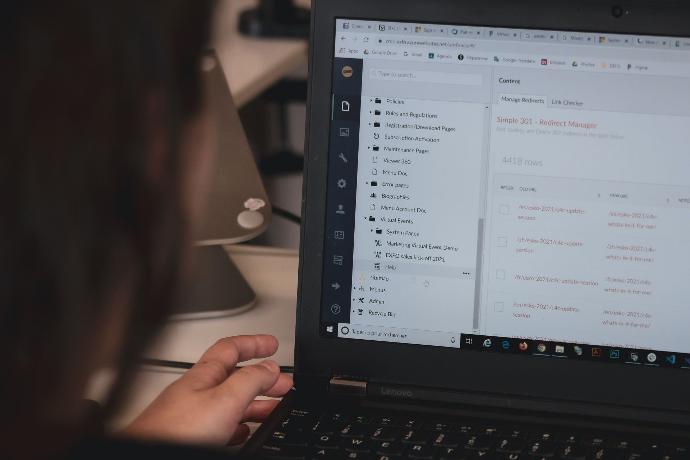

Documentation/Teamwork

Data and results can be shared from the Jupyter notebooks or via Streamlit.

GUI

The measurement results and data are displayed directly on our integrated Javascript-enabled GUI in Optimizer4D. The results can also be displayed with Streamlit or similar libraries in the network. The server can be hosted on an Optimizer4D.

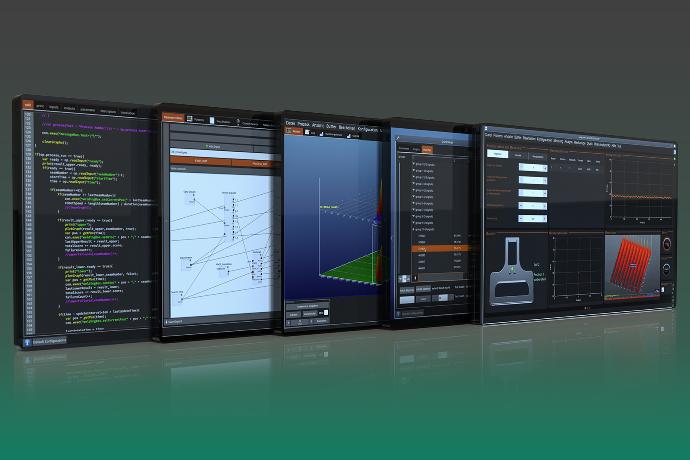

Tools for inline data analysis

Software and smart data analysis are at the heart of our solutions. It is the evaluation of the collected data that gives it meaning. Our system is designed to display complex data transformations intuitively and to be able to apply complex analyses during the measurement.

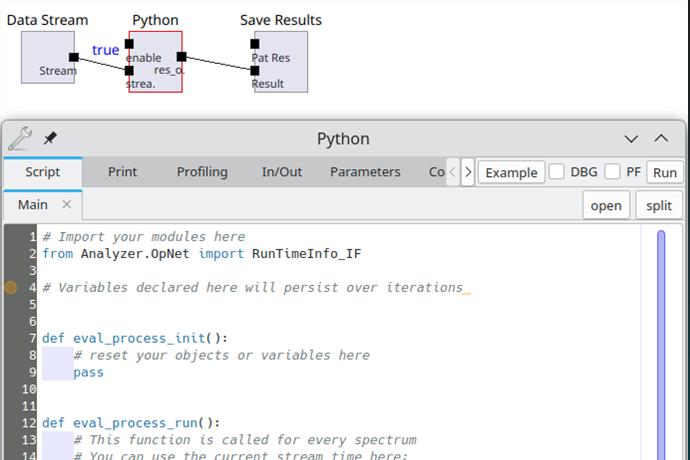

Python Integration

By integrating Python into our software, we create maximum flexibility for your projects and, of course, access to state-of-the-art machine learning libraries. To keep the entry hurdle as low as possible, we install libraries such as Numpy, Tensorflow, SciPy and many others on the Optimizer4D before delivery.

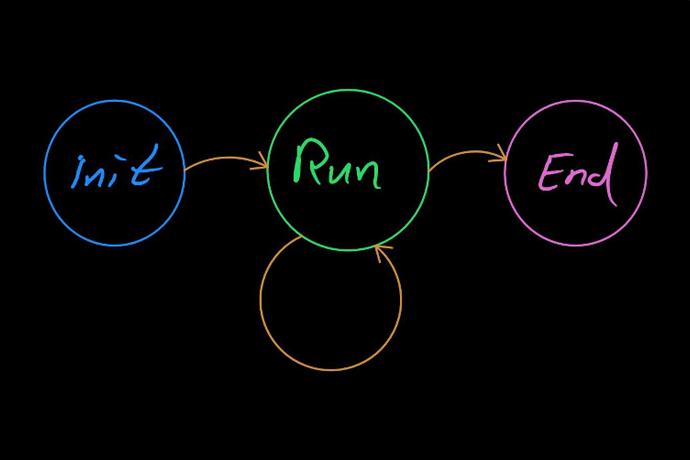

Python Operator

The Python Operator is one of our analysis modules for graphically programmable real-time analysis and yet it is completely different. This operator allows you to implement your own analysis approaches and apply them to the data stream in real time.

QASS Open Source Libraries

The Analyzer4D software comes with a network interface that can be used to control the measurement sequence, for example. Measurements can be started and stopped. Parameters can be set in the settings and application variables can be defined in the software.

Maschine communication

The trigger system is a sequence and communication controller within the Analyzer4D software. This controller is similar to a mini PLC, in which a type of program is executed cyclically, analogous to the PLC of a large machine controller.

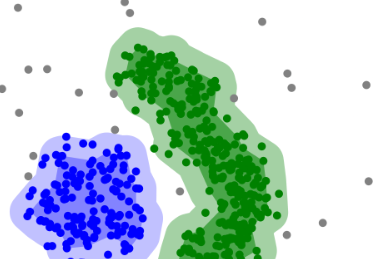

Clustering

Pattern recognition and clustering of sporadically occurring micro-crack signals.

Fancy more? Take a look at our YouTube channel!

some industrial customers, universities and institutes

with QASS measurement technology and software

-

KIT: Karslruher Institut für Technologie

-

RWTH AACHEN

-

TU Dortmund

-

Hochschule Furtwangen

-

Universität Stuttgart

-

TU Berlin

-

TU Braunschweig

-

Universität Bremen

-

Universität Hannover

-

TU Bergakademie Freiberg

-

DHBW: Duale Hochschule Baden-Wüttemberg

-

Hochschule Bremerhaven

-

FH Bielefeld

-

KTH Vetenskap Och Konst

-

Ruhr Universität Bochum

-

FAU: Friedrich-Alexander Universität Erlangen-Nürnberg

-

University of Southampton

-

Otto von Guericke - Universität Magdeburg

-

Hochschule Pforzheim

-

HAW Hamburg

-

Hochschule Esslingen

-

Technische Universität Ilmenau

-

Technische Universität Dresden

-

Hochschule Ravensburg-Weingarten

-

Hochschule Kaiserslautern

-

Fachhochschule Südwestfalen

-

Universität Augsburg

-

Hochschule Wismar

-

BAM

-

viele Fraunhofer Institute

-

Mercedes Benz

-

Daimler

-

MAN

-

Volkswagen

-

Audi

-

Skoda

-

BMW

-

Stellantis

-

Renault

-

Honda

-

Jaguar

-

Hyundai

-

Fiat

-

Ford

-

General Motors

-

Harley Davidson

-

SpaceX

-

Scania

-

Volvo

-

Tata Motors

-

Toyota

-

BYD

-

Great Wall

-

Siemens

-

Thyssen Krupp

-

Salzgitter AG

-

Mannesmann

-

Voestalpine

-

Benteler

-

Deutsche Bahn

-

Fendt (AGCO)

-

John Deere

-

Caterpillar

-

Stihl

-

Hilti

-

Metabo

-

Zwilling

-

SMS

-

Bosch

-

ZF

-

Continental

-

Schaeffler

-

Magna

-

GKN

-

Eaton

-

Dana

-

Samsung

On selected university and research projects

Find out more about some of our university projects.

Get in touch with us!

We will be happy to help you.