Optimize your tube production

Cracks, chatter marks or other production problems: We offer you innovative solutions!

QASS assists throughout the entire pipe production pipeline

With the technologies developed by QASS, you maintain full visibility over every step of your tube production.

During the drawing process, QASS analyzes the machine's behavior and intervenes proactively to reliable prevent chatter marks. At the same time, this enables a higher average drawing speed - often by more than 20%. As a result, you increase both quality and productivity.

With the specially developed µmag sensors, you can perform non-desctructive and continuous hardness measurement of your coils, thereby consistently guaranteeing the highest possible quality of the base material.

During subsequent internal scraping during pipe welding, we analyze the wear of your tool in real time and make predictions about the optimal time for tool replacement.

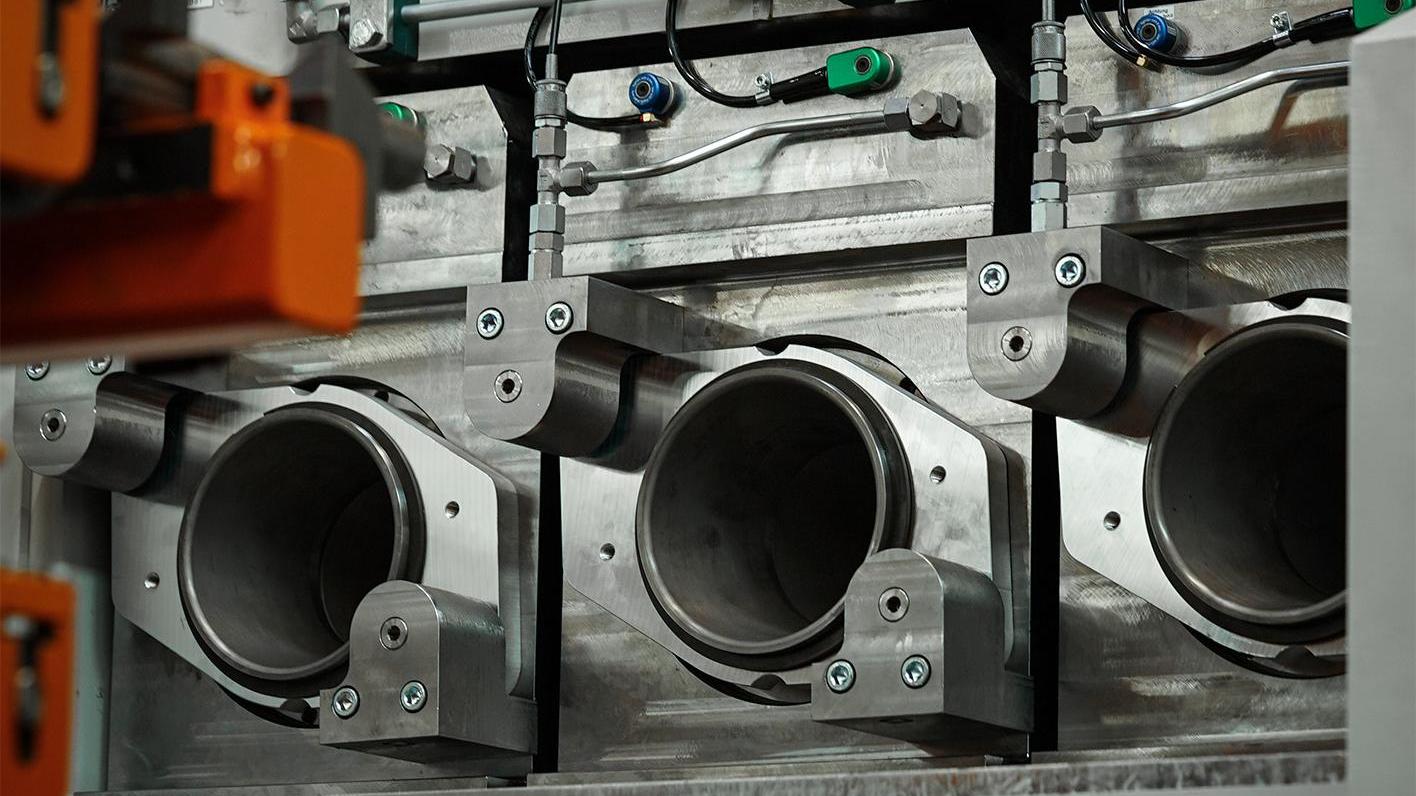

Prevent chatter marks & increase productivity

How to reliably avoid chatter marks while achieving higher drawing speeds.

Real-time hardness testing of strip steel

Test your steel strips' hardness non-destructively and contactlessly after heat treatment.

Tool Monitoring Internal Pipe Scraper

Analyze the tool wear of the internal pipe scraper when cutting internal longitudinally welded pipes.

The QASS project workflow

The QASS project workflow

Request

You contact us, by phone or by mail, and describe your situation.

Target definition

We define the goals of the project together with you.

Data analysis

QASS measurement equipment is installed and collects data that is subsequently analyzed.

Application

The measurement technology is specially adapted to your purposes.

Evaluation

Our system is tested and optimized at your site under production conditions.

Arrange a consultation appointment now!

Ask our experts about the possibilities for your industrial processes without obligation.