Zelos system for homogeneity testing

Our system solution for testing powder metallurgical components and green compacts.

Zelos plant for

homogeneity testing

of powder metallurgical components and green compacts

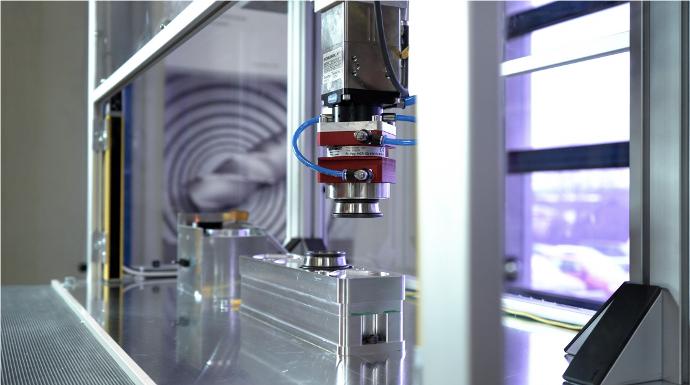

The Zelos system was developed by QASS with the aim of supporting companies in quality assurance in sintering. Zelos is an automated laboratory system for checking the compaction of sintered components. zu unterstützen. Zelos is an automated laboratory system for checking compaction in sintered components.

The measuring system installed in the system is the QASS Optimizer4D with µmagnetic- the micromagnetic extension for hardness testing, grinding burn testing and segment density testing for sintered parts and green compacts.

Zelos features

Features at a glance

Ease of use and overview

Adaptive user interface specifically tailored to the plant combines adapted configuration, control and results display for the user.

Flexible adaptation

Not only the number of specimens to be tested, but also the number of measuring positions as well as the number of measuring repetitions per position and tolerance limits are freely adjustable.

Can be integrated in series

The Zelos system can be easily integrated into existing series production.

Procedure of the homogeneity test

Homogeneity testing of green components with the Optimizer4D

Gentle component handling

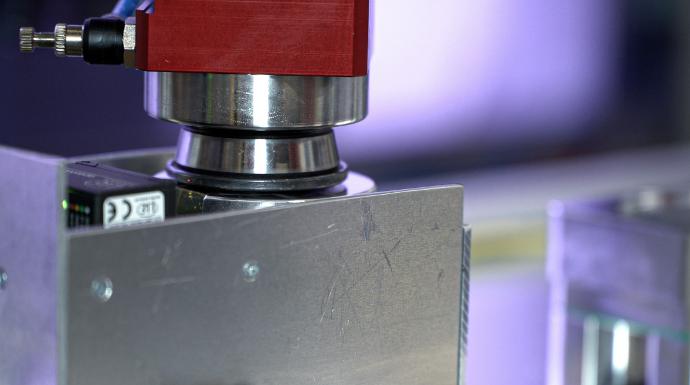

Test specimens are gently removed from the holder by means of a pneumatically controlled magnetic gripper and guided to the micromagnetic sensor via two linear axes.

Micromagnetic measurement

Our sensors record Barkhausen signals generated in response to magnetization by an external alternating magnetic field.

Analysis with the Optimizer4D

The Barkhausen signals are processed in the Optimizer4D by the Analyzer4D software and evaluated using spectral analysis, pattern recognition and energy detection.

Arrange a consultation appointment now!

Ask our experts about the possibilities for your industrial processes without obligation.