Our fields of application

Individual solutions for various industrial processes

Find the right solution for your application

QASS offers customizable measurement systems and solutions for many different applications in the industrial sector. With our expertise we can make your industrial processes measurable. The data is analyzed in real time, digitized and used for the optimization of your process.

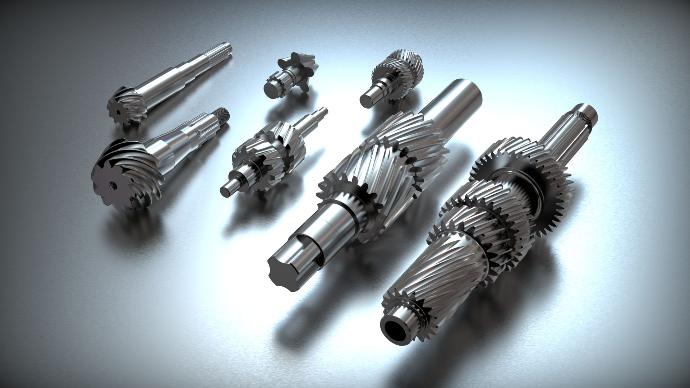

Straightening

Automotive groups and suppliers around the world rely on our expertise in crack prevention, process optimization and quality assurance. With the help of Optimizer4D, you can therefore not only precisely detect not only precisely detect cracks that occur during straightening, but also prevent them

prevent them. Our technology and services help you to the risk of failure of the steel shafts used.

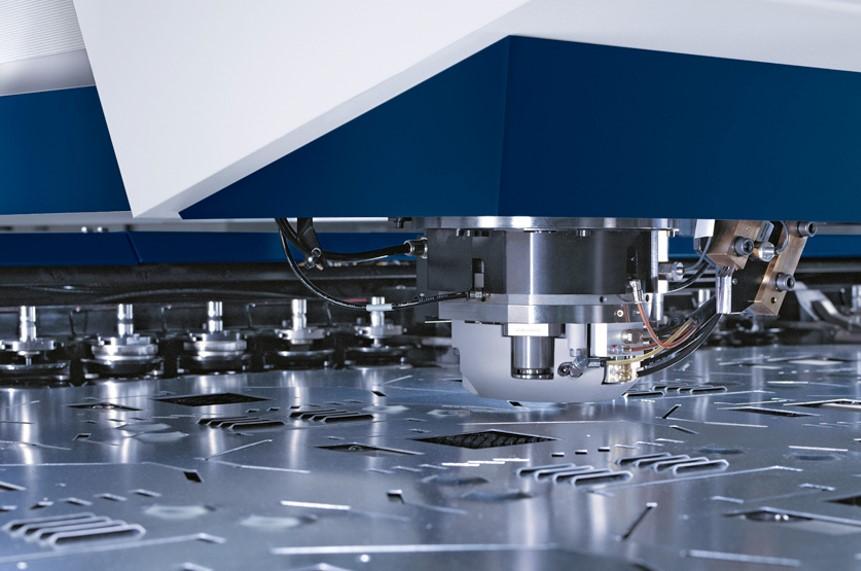

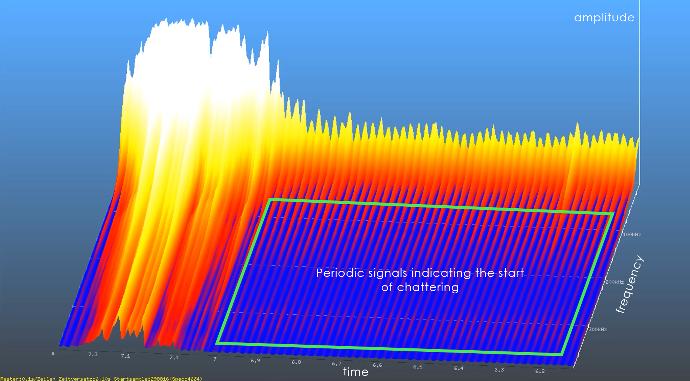

Tube drawing

With the aid of structure-borne sound analysis our process experts have succeeded in detecting the settling of the drawing process chatter marks and to implement an automated control system. control system. The measurements are documented documented and displayed.

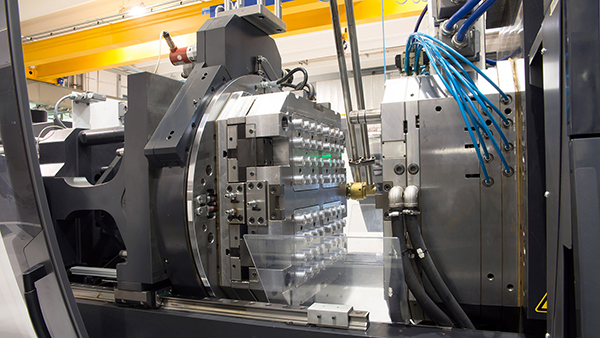

Assembly

With Optimizer4D, even hidden and visually inaccessible assembly processes that take place inside components, can be reliably checked. The QASS measuring system monitors assembly processes in-line via structure-borne sound and evaluates the process data generated process data in real time. Defective components or faulty process parameters can thus be detected as soon as they occur.

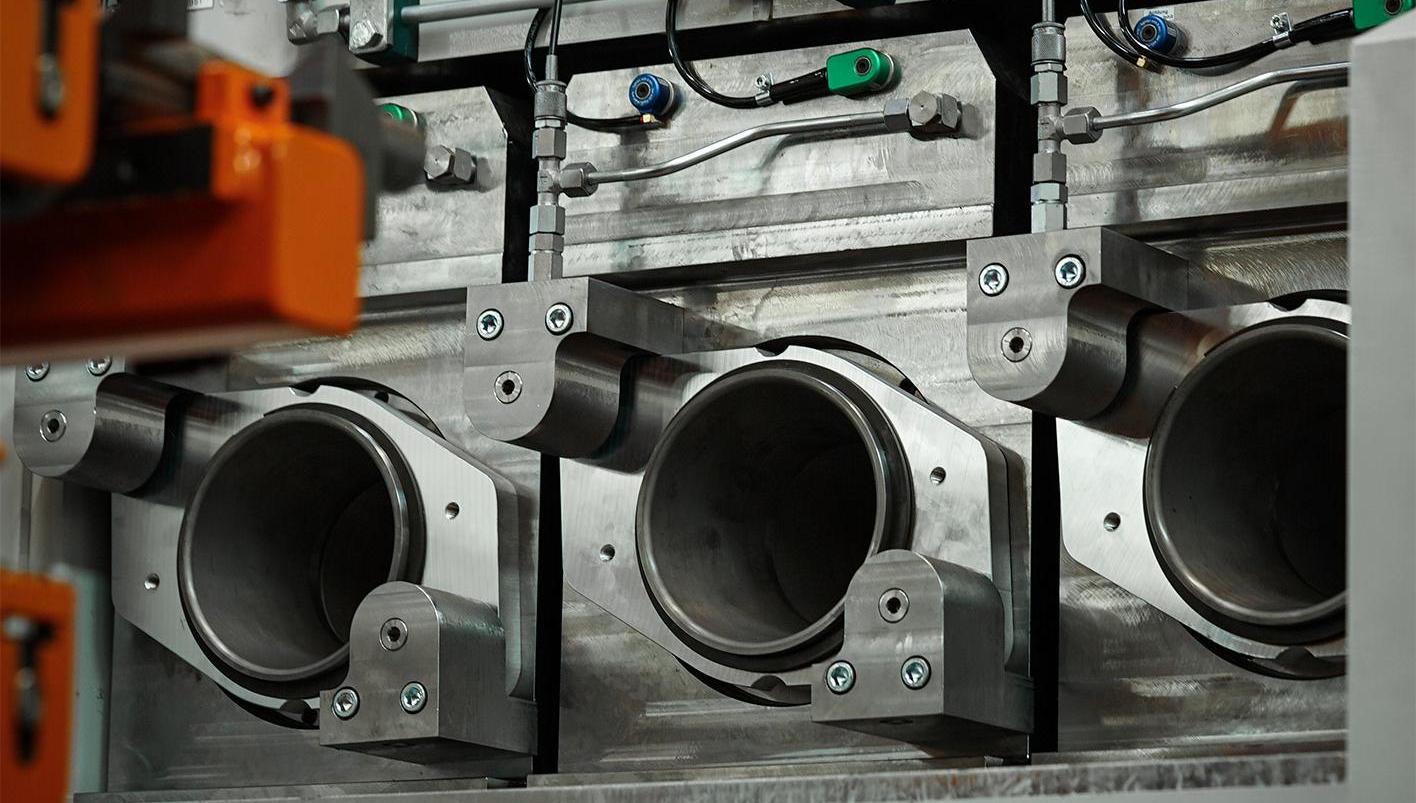

Structure-borne sound

Using structure-borne sound analysis, important process signals can be captured in real time. Our measurement system can evaluate these signals and react accordingly to optimize your process.