QOBOT Handling System

Our system solution for µmagnetic measurement processes

Our system solution for µmagnetic measurement processes

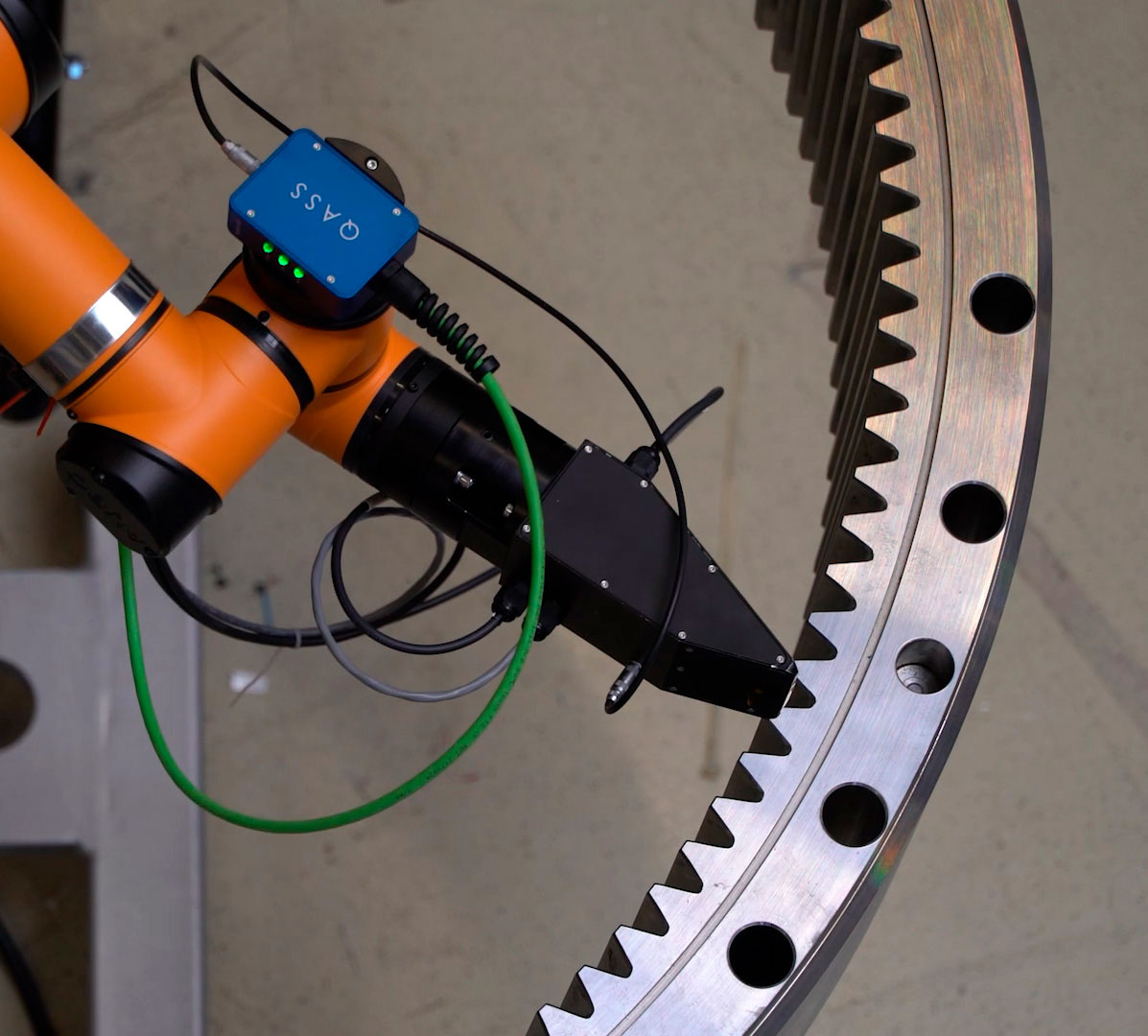

Our QOBOT handling system combines sensor technology and robotics in a smart way. It is an extension to the µmagnetic technology and can be acquired together with this technology in a system solution.

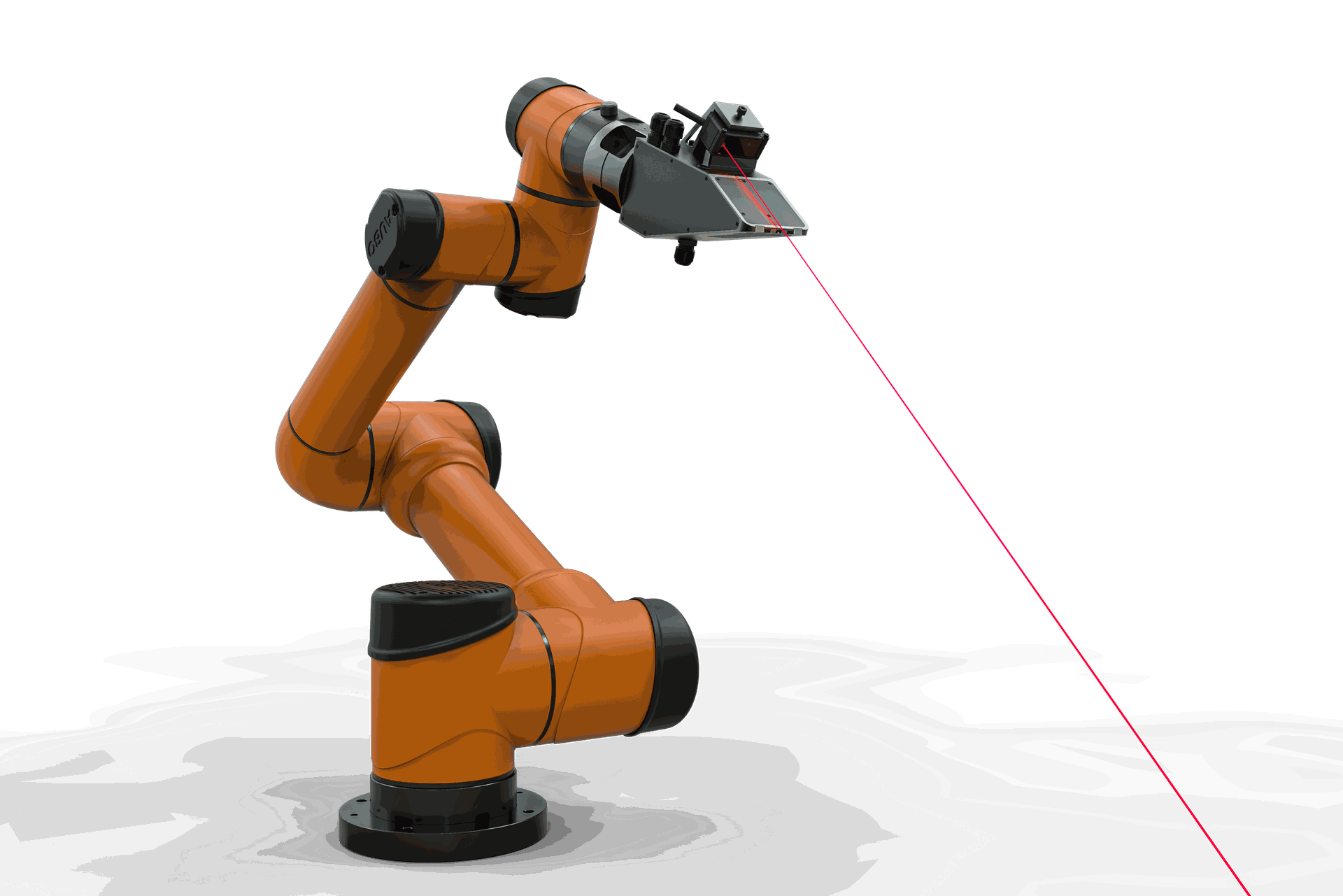

The synergy of sensor technology, robotics and innovative measuring technology allows to determine hardness curves for ferromagnetic materials in an efficient manner. QASS adapts the QOBOT handling system to the process and the manufacturing environment. As it is equipped with an AUBO-i5 Co-Bot, the handling system offers great flexibility*. Thanks to a freedom of movement of 6 DoF and a reach of 924 mm** it is possible to analyze the hardness of components of different geometries and lengths. A laser distance sensor captures the robot path and ensures that the µmagnetic sensor is correctly positioned during measurement***. The sensor and robot technology built into the QOBOT is integrated with the measuring system.

*IP classification: IP54; Ambient temperature: 0 ≤ 45°C; Ambient humidity: ≤ 75% RH (without frost or dew), on a short-term ≤ 85% RH

**Working range: (+/-) 175°; 880 mm

***Moving speed: ≤ 1000 mm/s

more about µmagnetic

Your Advantages at a Glance

Determination of hardness curves

The QOBOT can be used to dynamically record hardness profiles. The mechanical hardness as well as changes in the hardness of components can thus be determined precisely (e. g. to check components for grinding burn).

Even for complex component geometries

Through the interaction of a flexible robot arm and a laser distance sensor, the µmagnetic sensor can be perfectly adjusted to the component geometry.

Flexible integration

The QOBOT handling system can be utilized pre-, in- and post-process. The AUBO-i5 built into the handling system offers a high level of flexibility, which allows QASS to customize the QOBOT to your process and manufacturing environment.

Human-machine collaboration

The QOBOT handling system is based on collaborative robot technology, which is equipped with the necessary safety functions to enable a direct interaction between humans and robots.

more about detecting grinding burn

QASS as Your Technology and Engineering Partner

QASS has almost 20 years of experience in sensor technology, component monitoring, quality assurance, and process optimization. We are an innovative company that is continuously and successfully expanding into new business fields such as hardness measurement.

Our own R&D work and research projects in cooperation with renowned academic institutions and well-known companies form the basis for our know-how. It is no coincidence that industrial companies worldwide rely on our broad expertise and our innovative capability.

However, QASS does not simply develop and deliver measurement technology. We support you as an advisor on your way to maximum process optimization. Together we realize an ideal process flow and set new standards in terms of quality and collaboration. Innovation and progress are always at the core of our activities.

Your Benefits at a Glance

Custom development

Together we find a solution that meets your expectations and fulfils the requirements of your process. Benefit from our many years of experience and our inventive talent.

Complete solution

The QOBOT is an integrated handling system developed by QASS. Its hard- and software are perfectly matched and can be optimally integrated with the µmagnetic technology.

Extensive Service

At QASS we consider ourselves as a technology partner. We are there for you when you need us. Through flexible telephone, remote and on-site support, we ensure the continuity of your process.