Grinding burn detection

Detect invisible production defects non-destructively, automatically and reliably with the QASS measuring system

Automatic detection of grinding burn

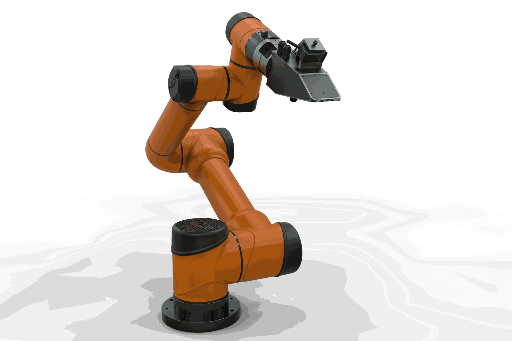

QASS enables the non-destructive detection of grinding burn. The robot system allows a completely automated integration of our measuring systems into your processes.

Customization

Thanks to open software architecture and free access to extensible software libraries, we can implement customized individual function algorithms.

Very high measurement accuracy

Compared to manual handling systems, QASS offers high repeatability of measurement checks even for complex geometries.

100% monitoring of the production

The automated robotics solution allows for integration into existing manufacturing and production lines to enable complete monitoring of your production.

Features Overview

|

|

Grinding burn can drastically reduce the lifetime of your components. Since grinding burn cannot be seen with the naked eye, this common production defect often goes unnoticed. QASS has developed a measurement system that enables non-destructive and non-contact inspection of your production lines.

Grinding burn is a phenomenon that occurs when steel is unintentionally heat treated with excessive grinding energy and in the absence of cooling. Among other things, softer tempering zones and hard and brittle rehardening zones can develop on the material. These deviations can result in changes in hardness, microstructure and residual stress. The consequence is a reduction in the wear resistance of the material. This favors the formation of cracks and chipping under dynamic stress.

Wear-free detection of grinding burn with the QASS measuring system

The magnetic structure of ferromagnetic metals can be used to obtain non-destructive and wear-free information from the material. Conclusions about the mechanical properties can be drawn from the magnetic behavior. Changes in the mechanical properties cause changes in the magnetic behavior. The QASS µmagnetic measuring system measures and visualizes this changed behavior by exploiting the Barkhausen effect.

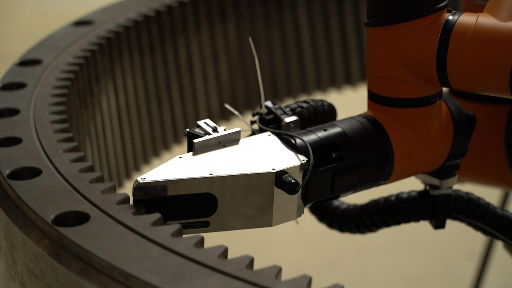

In grinding burn detection, the material is scanned line by line with a micromagnetic sensor. The material to be measured is exposed to an alternating magnetic field. The reorientation of the individual magnetic domains in the microstructure of the material is measured. The QOBOT handling system with laser distance sensor ensures the correct positioning and traversing of the µmagnetic sensor during the measurement. The Barkhausen signal is calculated in real time with the distance values to obtain highly accurate measurement results. The time-amplitude signals acquired by the µmagnetic sensor are digitized by the QASS µmagnetic measurement system and processed in real time by a Fast Fourier Transform (FFT).

Machine and interference noise can be specifically filtered out of the signal data within the framework of spectral analysis by means of a spectral filter (also known as a frequency mask). This improves the ratio between useful and interfering signal.

Process optimization based on the QASS grinding burn test

Grinding burn can be accurately measured and localized on all ferromagnetic materials with the QASS measuring system by relative differences in magnetizability. Be it a gear shaft for a passenger car or a gear wheel for a ship's gearbox, with the µmagnetic measuring system the inspection of the entire material for grinding burn is fully automatic. The machine operator only has to make a few entries - the QOBOT handling system takes care of the inspection and measurements. While the material is automatically removed, the data is processed in real time and documented in a database.

The advantages for the manufacturer are obvious. Besides the information about the condition of your manufactured components, the machine parameters can be optimized with the data obtained.

Arrange a consultation appointment now!

Ask our experts about the possibilities for your industrial processes without obligation.