More quality in straightening

Less pseudo scrap and highly precise crack detection in the process

More process reliability

Through permanent monitoring with the QASS measuring system, you keep the entire process under control. Cracks are already detected and signaled in the process by means of pattern recognition.

Easy Retrofit

We can easily equip any straightening machine with our measuring system. Our retrofitting does not require an update of the straightening machine.

Less pseudo scrap

Due to difficult acoustic boundary conditions, not all measuring systems can reliably detect cracks during the straightening process. The Optimizer4D uses frequency filters that filter out all disturbing machine noise, making every crack detectable in the software.

Individual Service

Benefit from remote assistance and regular optimization of our system. We support you in every phase of the changeover to Optimizer4D and are available to address any issues. We are also happy to carry out customizations tailored to your needs.

Crack detection during straightening processes with the Optimizer4D

During bend straightening, point loads are applied perpendicular to the longitudinal direction in order to achieve concentricity within defined tolerances through plastic deformation of the metal. Typically, hardened shafts from the automotive engineering are straightened using this method.

Errors during bend straightening can occur if the tensile stresses during straightening exceed the local tensile strength of the material, often resulting in brittle cracks in the hardened area of the shaft.

The Optimizer4D eliminates the need to manually check components for cracks. Using structure-borne sound, all sounds during the process are registered by our sensors. The interfering signals are filtered out of the structure-borne sound signals, and through pattern recognition, the resulting process signals are automatically categorized. Our measurement technology works with high precision and can be individually adapted to your process. This ensures reliable detection of cracks and significantly reduces pseudo scrap.

You are using the CiS.01 system?

Upgrade now!

Optimizer4D takes your crack detection to a whole new level. With its powerful new features, you can save valuable resources and money!

Find out more now and request a non-binding offer.More information

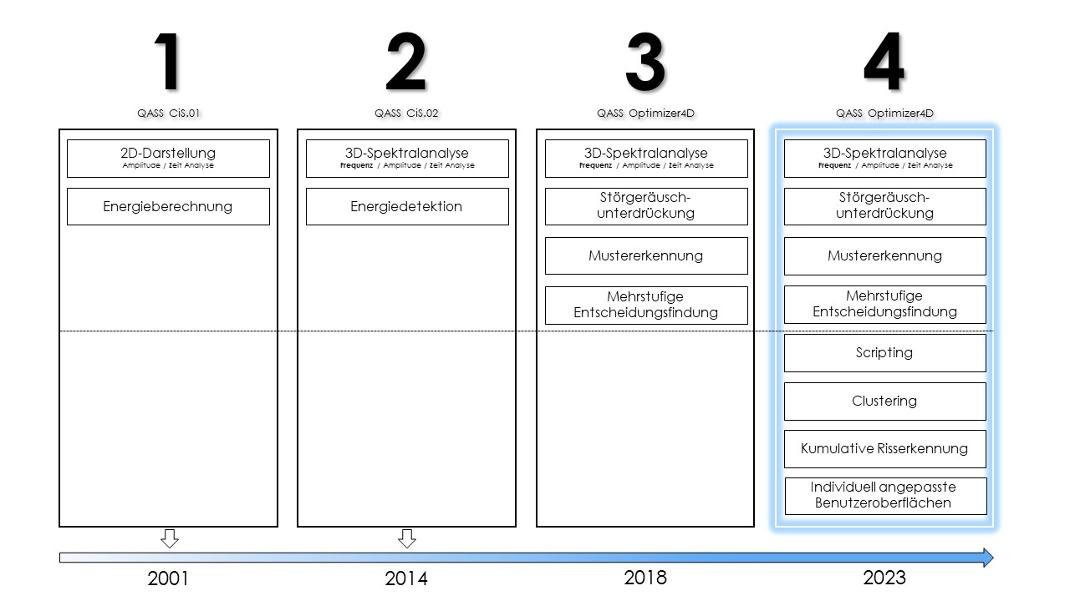

Development of QASS crack detection

Arrange a consultation appointment now!

Ask our experts about the possibilities for your industrial processes without obligation.