Crack detection and monitoring in spring manufacturing

Detect cracks reliably and automatically with the QASS measuring system.

Inline crack detection

QASS enables real-time crack detection when coiling springs. We monitor every millisecond of the process and any defective components are automatically ejected from the system.

Data analysis through pattern recognition

Real-time evaluation of measurement data using pattern recognition: cracks are detected and analyzed using stored signal patterns. This is followed by the immediate transmission of the result (IO/NIO) via a standard PLC interface.

Full quality control

Coiling and winding processes are seamlessly monitored by our structure-borne sound sensors, minimising the need for downstream quality checks. The system works fully automatically and visual samples are no longer necessary.

100% non-destructive monitoring

Due to our measuring principle based on structure-borne sound, our sensors record all the details of your process completely non-destructively.

Crack detection in spring production

Seamless monitoring during spring production for maximum quality and safety

In spring production, the aim across all industries is to increase safety standards and counteract problems such as cracks and defects. Efficient quality assurance during production is crucial in order to detect such damage at an early stage and avoid replacement processes.

During production, springs go through several stages, including cold forming, tempering and setting. During cold forming, springs are subjected to high compressive and tensile forces, which has a significant impact on their mechanical properties, particularly their strength and flexibility. Despite advanced technologies, visual inspection by humans often remains necessary as a final safety measure, as techniques such as Magna-Flux can be ineffective with the large number of springs.

For quality assurance, QASS has developed a complete system that enables automatic and real-time detection of cracks. Pattern recognition is used to identify crack patterns in the overall vibration pattern. The Optimizer4D measuring device plays a central role here, as it provides this analysis methodology for series production, including machine communication. The introduction of structure-borne sound sensors, which are already standard in the automotive industry, enables precise crack detection and guarantees 100% crack-tested delivery.

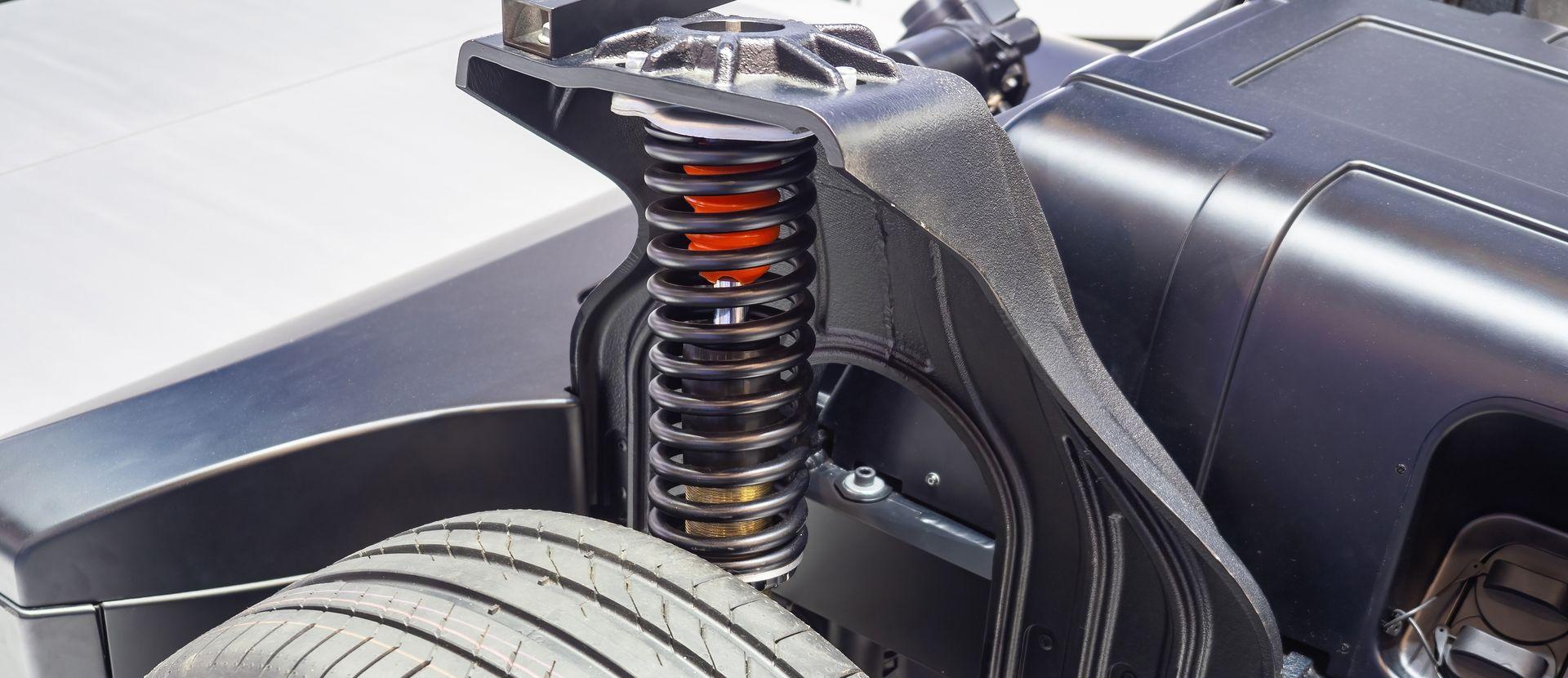

Figure 1: Detailed view of a vehicle spring

Figure 1: Detailed view of a vehicle spring

Figure 2: Close-up of a cracked vehicle spring

Your branches

Automotive

Aerospace

Wind energy

Medical technology

Mechanical engineering

How it works

The QASS Optimizer4D in use.

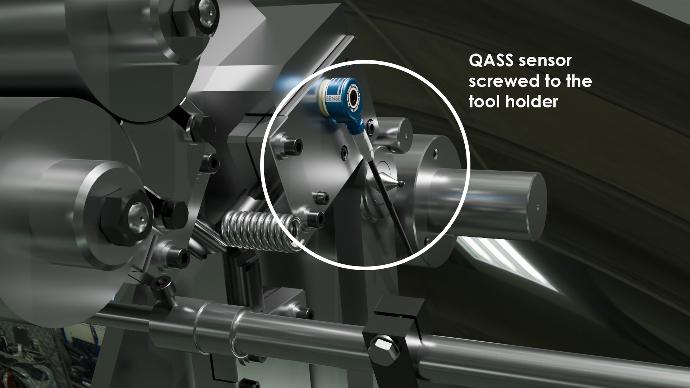

Install QASS sensor

The structure-borne sound sensors are installed on the coiling or setting machine. When winding wire, friction and forming forces occur within the machine, which generates noise.

Although these noises are not perceptible to the human ear above a frequency of 20 kHz, they are transmitted within the machine and can be detected by QASS sensors.

Even the smallest differences from the standard produce deviations in the overall emission pattern during the forming process. A simple screw connection to the machine is important so that the vibrations and emissions of the process are transmitted through the material to the sensors.

QASS sensor screwed to the tool holder.

QASS sensor screwed to the tool holder.

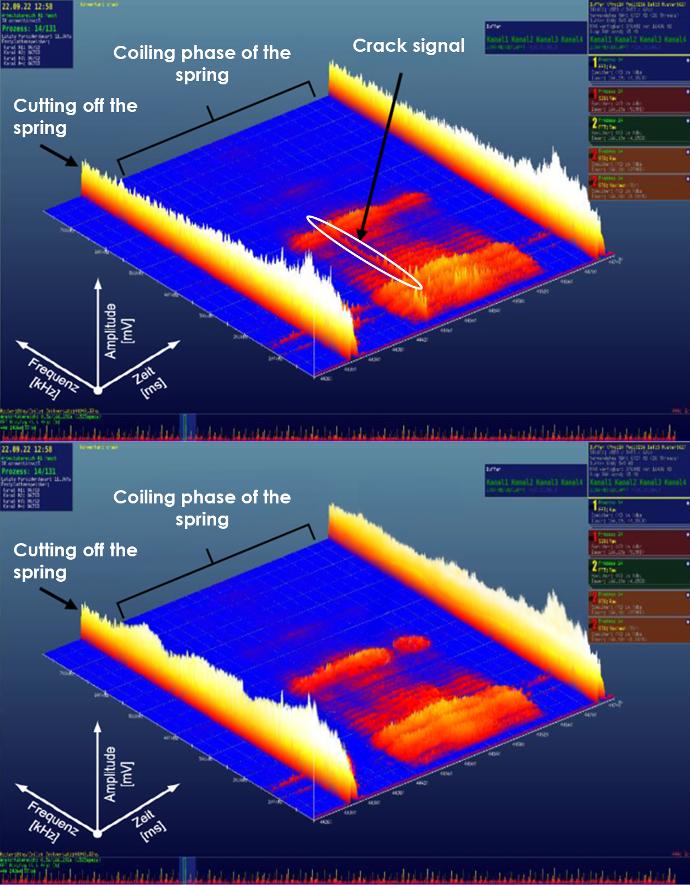

Structure-borne sound image of a coiling process of a spring in the QASS Optimizer4D measuring system. (With and without crack)

Structure-borne sound image of a coiling process of a spring in the QASS Optimizer4D measuring system. (With and without crack)

Whenever a crack occurs in solid material due to forming forces pressure waves run through the component. The stronger the structure, the greater the intensity of this wave. It is important to distinguish these emissions from normal machine noise.

The "Optimizer4D", our high-performance measuring system that can record and evaluate structure-borne sound data in real time, is used for this purpose. This makes it possible to detect the occurrence of cracks and sort out the damaged component.

The QASS spectral analysis makes it possible to separate all working and interference noises from the machine so that even micro-cracks can be reliably detected as they occur.

The recorded structure-borne sound signals can be displayed and tracked in our FFT landscape, as shown in the image (left). Our essential features such as clustering and the associated pattern recognition, as well as corresponding frequency filters and masks, enable us to precisely separate important signals from interference or machine noise and analyze them within milliseconds.

The Optimizer4D can be used for more than just detecting cracks. Structure-borne sound data are fingerprints of manufacturing processes and machines. If elements of the tools, such as wind pins or guide rollers, wear out, this can be recognized in the structure-borne sound data. Defective primary material emits different signals than good quality primary material. QASS provides its customers with deeper insights into their processes, indicates at an early stage when machines require maintenance and provides its customers with important information about the primary material supplied by the wire manufacturer.

Users of QASS measurement sensors benefit from

- Reliable crack and micro-crack detection

Cracks that reach critical size can be detected and ejected by Optimizer4D. A warning is automatically forwarded to the system.

- Monitoring of the tool condition (Tool monitoring)

Our measurement system not only enables the detection of cracks, but can also detect damage to the machine tools (e.g. wear on the wind pins) - Quality assessment of the primary material

Based on characteristic differences in the structure-borne sound data, we can draw conclusions about cracks in the primary material.

Detecting cracks, evaluating primary material, detecting wear on the coiling tool, tracking machine trends - the Optimizer4D makes all this possible.

Scope of delivery:

Optimizer4D Measurement system

2TB SSD Hard disk

Optimizer4D measuring chain ( preamplifier, structure-borne sound sensor, cable )

12“ o. 15“ Touch Display

The Optimizer4D is intended for installation in a machine control cabinet. This must be air-conditioned or have ventilation.

Options:

8TB hard disk instead of 2TB

Optimizer housed in its own control unit (at an extra charge)

Accommodation of the Optimizer in a mobile "expert case" (at an extra charge)

Machine communication:

24V/IO-Communication ( inclusive )

ProfiBus ( at an extra charge )

ProfiNet ( at an extra charge )

Graphical User Interface ( GUI )

The Optimizer user interface has several levels. The top level, which is visible to everyone, is the "PenGUI", a customizable interface on which the simplest information can be viewed easily and intuitively. Crack rates, trend developments or simple "red"-"green" displays provide the machine operator with the necessary information quickly and clearly. If someone with higher access rights logs in, they can delve deeper into the process, view signals in their raw state, adjust the pattern library, etc. The focus is on displaying only the absolutely necessary data on the machine.

Request

You contact us by phone or e-mail and tell us about your situation

Target definition

We define the goals of the project together with you.

Data analysis

The QASS measurement technology is installed and records data, which is then analyzed.

Application

The measurement technology is specially adapted to your purposes.

Evaluation

Our system is tested and optimized at your premises under production conditions.

Arrange a consultation now!

Ask our experts about the possibilities for your industrial processes without obligation.