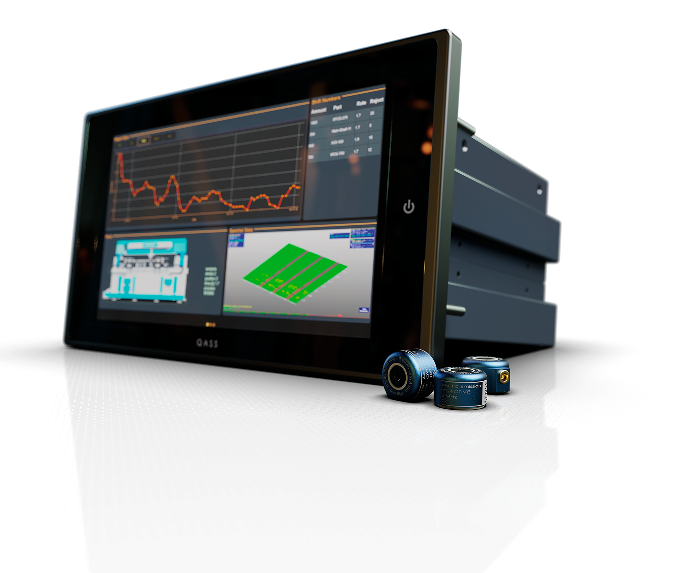

Optimizer4D

The cognitive measurement system

Efficient monitoring with

maximum selectivity

The Optimizer4D is a high-performance industrial computer that is constantly adapted to the latest hardware status and has enormous deep memory capacities. It serves as a measurement system for monitoring processes, detecting cracks, hardness testing and analyzing data.

The extreme sampling rate of 50 MHz allows us to measure what can otherwise only be simulated:

- Tool wear,

- Micro-damage in the component,

- Temperature changes in the material,

- Noise in the machine.

This is process monitoring in-line and non-destructive.

Also available in the mobile QASE.

Also available in the mobile QASE.Direct interfaces for machine communication (BUS, IO interfaces/PLC, TCP/IP) allow continuous process optimization and direct adaptation to the production environment.

Our high-performance measuring card with 4 simultaneously operating channels enables the processing of large amounts of data from a wide range of sensor types. Up to 8 preamplifiers and 48 sensors per measuring computer are possible.

Parallel Fourier transformation with 40 µs spacing per spectrum is the main feature of our integrated measurement card. Convenient and safe display of analog sensor data for easier referencing of production processes.

Technical Specifications

- Device Optimizer4D

- Mains voltage DC 10 – 28 V

- Rated current 6,25 – 12 A

- Power 150 W

- Ambient temperature 0 – 50° Celsius

- Protection class IP 3X housing

- Protection class according to IEC 417 1

- Insulation voltage 1000 V DC

- Overvoltage class II

- Pollution class II

- EMC Standards CISPR 22 ( EN 55022);IEC 1000-4-2,3,4,5;IEC 1000-3-2

- Safety Standards IEC 60950-1, UL 60950-1

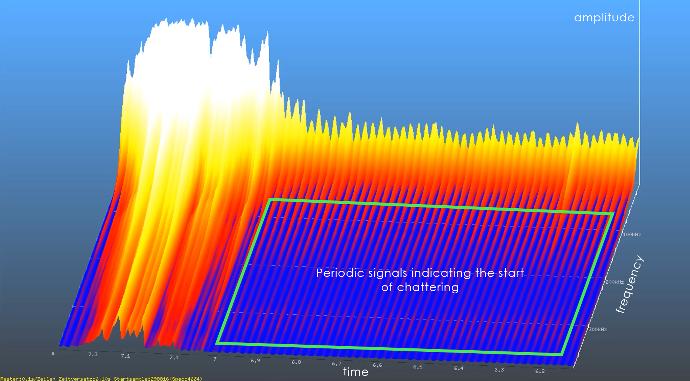

Measurement method structure-borne sound

Using structure-borne sound analysis, important process signals can be captured in real time. Our measurement system can evaluate these signals and react accordingly to optimize your process.

Arrange a consultation appointment now!

Ask our experts about the possibilities for your industrial processes without obligation.