Our products

We offer individual solutions for your industrial processes

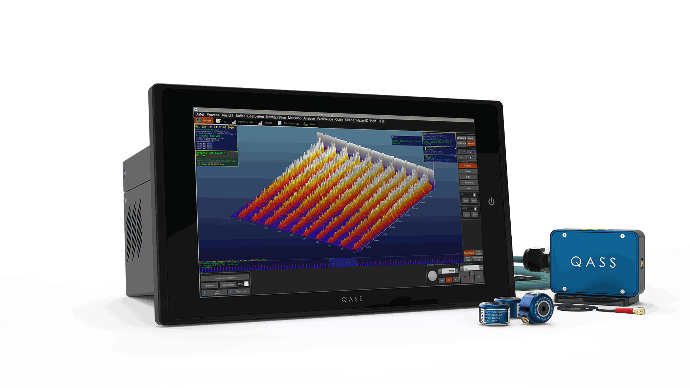

Our measuring system as a product solution

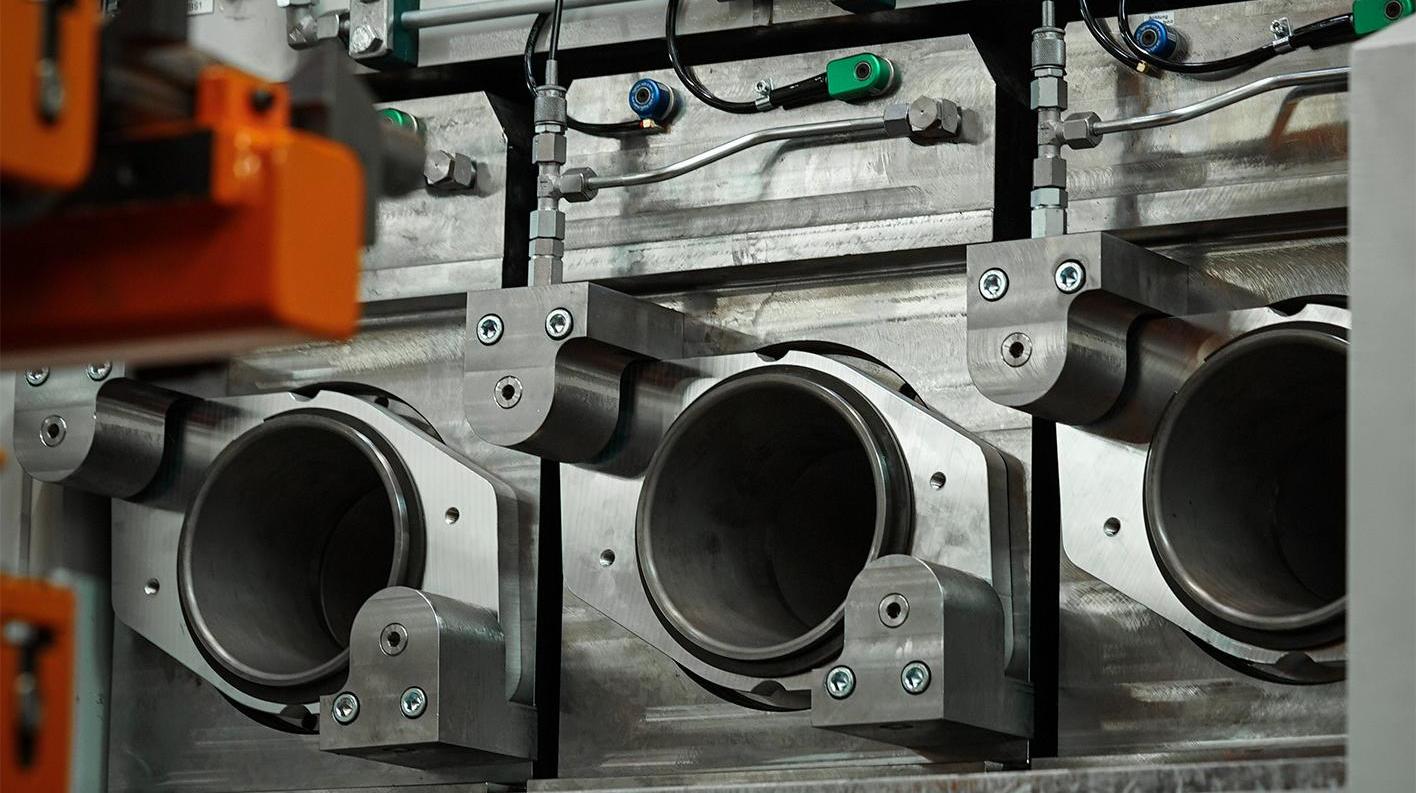

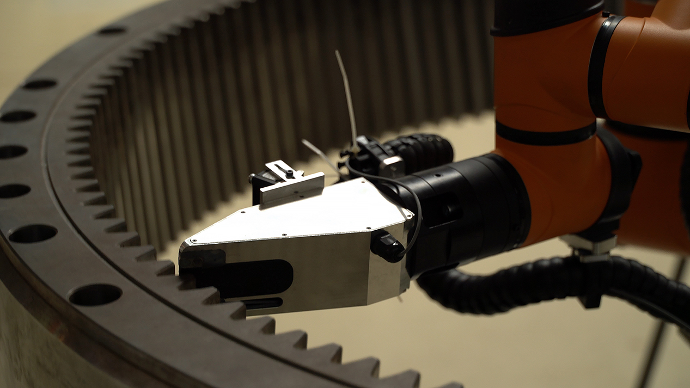

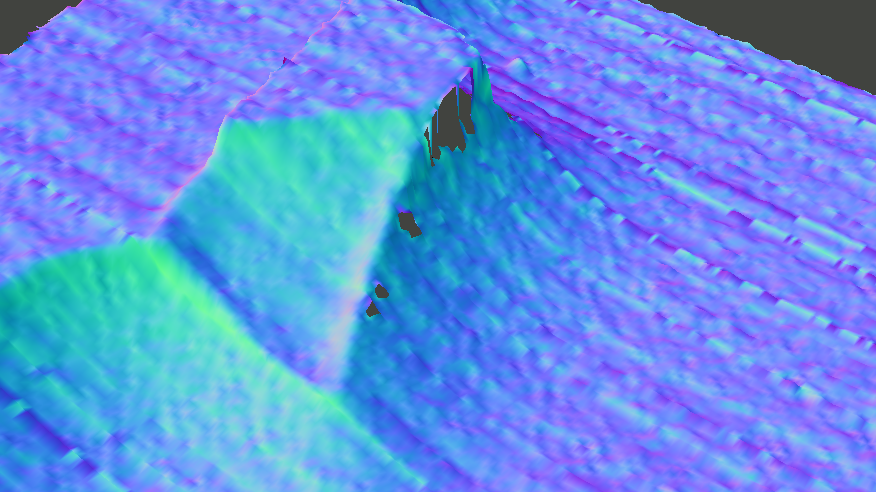

Not only in crack detection do we supply high-precision measurement technology; we can also optimize industrial processes in many other areas. With our high-performance measuring computer, the Optimizer4D, we are able to evaluate and display huge amounts of data from sensors in real time. In-line quality monitoring, predictive maintenance and process documentation - we can offer you an individual product solution.

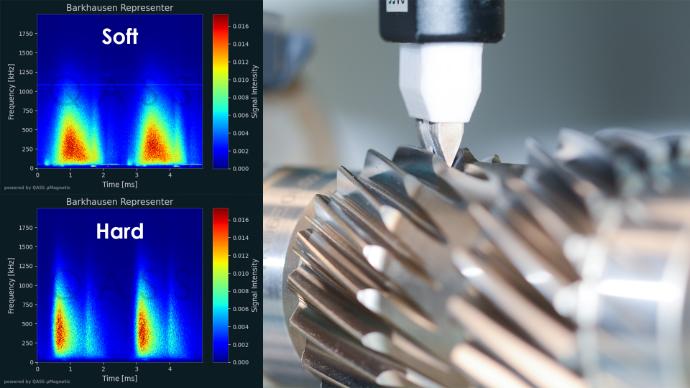

Structure-borne sound measurement

An industrial manufacturing process generates many noises simultaneously, many structure-borne sound signals. These overlap to form squeaks, rattles, etc. Optimizer4D identifies the actual sources of each noise through its high sampling rate, frequency analysis and pattern analysis.

How a project with QASS works

Request

You contact us, by phone or by mail, and describe the situation.

Target definition

We define the goals of the project together with you.

Data analysis

The QASS measurement equipment is installed and collects data that is subsequently analyzed.

Application

The measurement technology is specially adapted to your purposes.

Evaluation

Our system is tested and optimized at your site under production conditions.