Condition Monitoring

Keep a reliable eye on the condition of your machines

We make the condition of your machine measurable

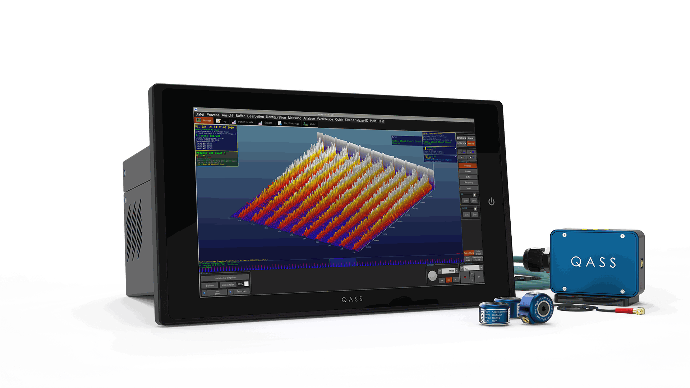

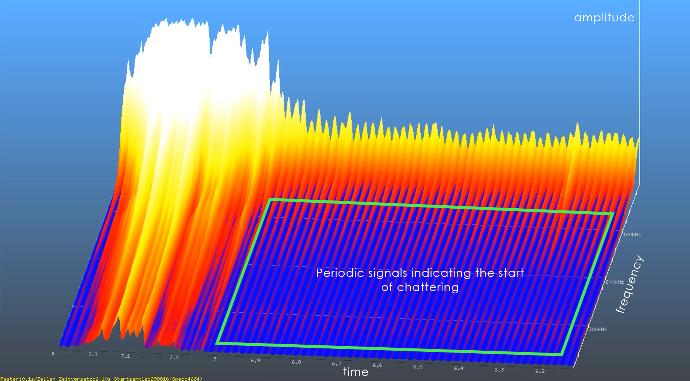

With our measuring system Optimizer4D in combination with our powerful sensors, we can make your industrial process measurable. With the help of structure-borne sound, we filter out and interpret important signals during the process. This enables us to reliably assess the condition of your tools and wear parts.

Detect tool wear

Condition monitoring from QASS can detect the condition of your tool. As soon as it is detected that the tool is worn, it can be replaced, thus avoiding quality losses in production.

Optimize maintenance cycles

Instead of cyclical maintenance after a certain time, the QASS measuring system allows you to determine the need for maintenance according to the condition of the machine. This allows you to safe both time and money.

Real-time analysis

Our measurement system can record, filter and display the structure-borne sound signals in real time during the process. See and understand your process in detail.

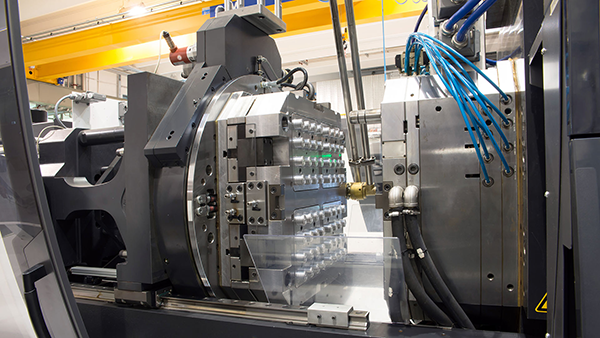

Condition monitoring in plastic injection molding

Venting channels in the injection mold tend to become clogged. The resulting excessively hot air can cause damage to the plastic parts. To counteract this loss of quality, we work closely with leading manufacturers in the industry to integrate and expand solutions such as condition-based maintenance of the machine in the industry.

Condition monitoring in wire drawing

With the QASS measuring system, several process information on section reduction, drawing speed and lubrication can be automatically monitored in the wire drawing. Based on this information, the most economical drawing speed for the process can be determined and automatically controlled by the Optimizer4D. Additionally, a detection of scoring formation is possible.

Condition Monitoring in machining

During machining, the Optimizer4D can monitor and detect the tool condition. Acoustic signals allow conclusions to be drawn about the condition of the cutting tool. The QASS measuring system detects fractures and worn tools, thereby reducing maintenance efforts.

We have sparked your interest? Contact us now!

We look forward to your concerns and questions and will be happy to help you further.