Geometry measurement

Precise geometry measurement of components for the detection of surface defects

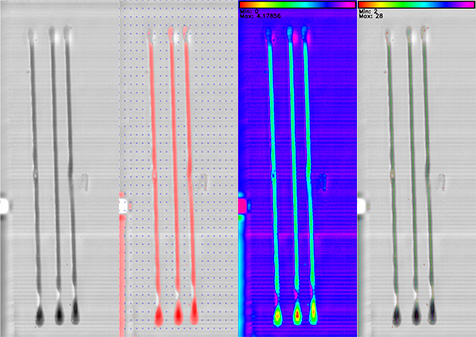

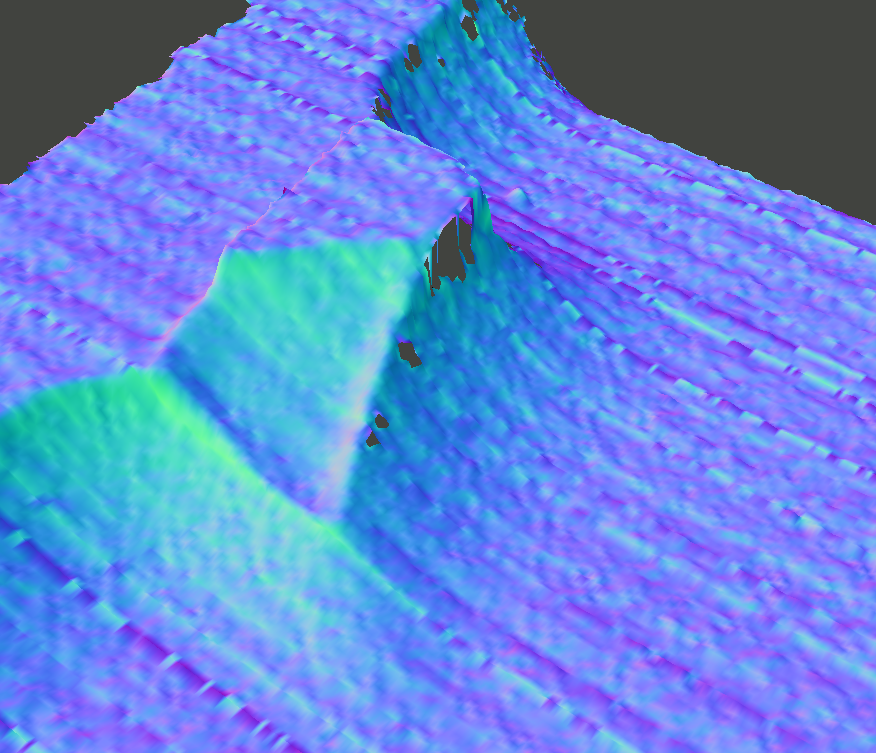

Detection of surface defects

With QASS Geometry Measurement, we scan your components and integrate them as 3D data into our evaluation analytics. Surface and structural defects become easily visible.

Customer and process specific solutions

QASS adapts solutions and system ideally to your process and requirements. If you need a special software interface, then we develop it. If you need an individual handling system, then we set up the QOBOT perfectly for you.

Versatile use

The QASS geometry measurement is versatile and can measure even complex geometries precisely with our QOBOT handling system.

Pre-, in and post-process

All QASS applications are possible upstream, in-process and downstream on the finished component. Inspect your objects and your material non-destructively and without contact.

Geometric measurement of structures and components

QASS has integrated various geometric measurement concepts into the Optimizer4D. In addition to acoustic data recording, 3D scans of your components can be made and recorded as 3D data points. We use this technology ourselves, for example, for the downstream inspection of weld seams or for the detection of surface defects. With the QASS QOBOTS, the sensors can be flexibly integrated into production processes or directly combined with other QASS measurement tasks.

All data can be backed up on integrated data storage devices (e. g. 2-8 TB on 2.5″ SSDs). All data can be analyzed in real-time using proven QASS methods such as spectral energy evaluation, pattern recognition or envelope comparison but also all Python-based analysis methods.

This also provides a wide range of machine-learning methods (e g. conversion of elevation data into color or grayscale images and processing e. g. with OpenCV).

Details

- High-resolution laser line scans (e.g. 2,000 measuring points 2,000 times per second) with a distance resolution of up to 5µm

- Distance point laser (e. g. 2,000 measurements per second) with a distance resolution of up to 5µm

- TOF-Kamera

- Webcam

- Induktive Abstandssensoren

QOBOT Handling System

The QOBOT handling system is based on an intelligent combination of sensors and robotics. It was developed by QASS especially for the µmagnetic technology and can be purchased together with it as a system solution.

The QOBOT is individually adapted by QASS to the process and the manufacturing environment. The system can be used pre-, in- and post-process. The AUBO-i5 Co-Bot installed in the handling system can be used flexibly and, thanks to its movement range of 924mm**, enables hardness measurement of components of different geometries and lengths. A laser distance sensor detects the robot path so that the µmagnetic sensor is correctly positioned during the measurement. The control of the sensor technology and robotics installed in the QOBOT is integrated with the µmagnetic measuring system.

Zelos system for segement density testing

The Zelos system was developed by QASS with the aim of supporting companies in quality assurance in sintering. The Zelos system is an automated laboratory system for checking the compaction of sintered components. The measuring system installed in the plant is the QASS Optimizer4D with µmagnetic – the micromagnetic extension for hardness testing, grinding burn testing and segment density testing for sintered parts.nd Segmentdichte-Prüfung für Sinterteile.

The Zelos system for testing sintered parts combines micromagnetic measurement technology with gentle component handling. Test specimens are gently removed from the fixture by a pneumatically controlled magnetic gripper and guided to the micromagnetic sensor via two linear axes. A laser distance sensor ensures the correct positioning of the test specimen.

Arrange a consultation appointment now!

Ask our experts about the possibilities for your industrial processes without obligation.