The Akuprolas research project was developed in cooperation with the Frauenhofer Institute for Non-destructive Testing IZEP, Department of Process Monitoring and Control.

It’s major project goals are:

1. Development of a measurement device for contact-less measurement of high frequency acoustic emissions that travel via air (20 kHz – 1MHz) during laser welding of ultra high strength steel.

2. Development of frequency adapted acoustic emission sensors (for emissions that travel through solid bodies) and pre-amplifyers for Optimizer4D to detect small band acoustic emission during laser welding.

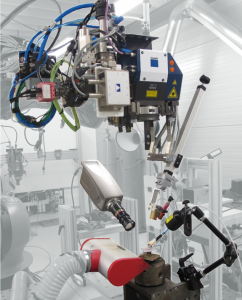

3. A prototype demonstrator by combining the developed measurement device (Position 1) and Optimizer4D, including frequency adapted acoustic emission sensors. This demonstrator is to be integrated into a laser welding machine in order to do systematic welding tests.

4.Correlate results with quality of welding seam and parameters of the welding process in order to determine power and limits of usage. On this basis, QASS is going to develop a concept for instrumentation and control of a laser welding process.

Project ran from February 1st, 2014, to August 15th, 2015.