It’s possible to control the quality of bending and straightening processes by analyzing acoustic emission. If cracks occur in a component, acoustic emission analysis will detect this.

Eliminate noise

Noise, mechanical or electrical influences may falsify results of acoustic emission analysis. This produces false rejection: Components are marked as faulty while they are perfectly okay. This produces unnecessary cost.

Optimizer4D-CiS.02

When it comes to crack detection for bending and straightening processes, QASS is the world market leader. With immediate effect, QASS recommends the new and improved crack detection system, custom-made for bending and straightening processes. Optimizer4D-CiS.02 applies a completely new analysis method and lowers false rejection rates that were unavoidable up to now.

This is how modern crack detection works

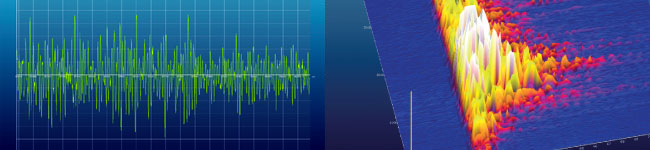

The graphic below shows on the left side acoustic emission of a cracked component, shown in the traditional way of depiction, on the axes time and amplitude. The right side shows the new analysis method of the QASS Optimizer4D-CiS.02. The three-dimensional analysis displays the axes time, amplitude and frequency. This is High-Frequency-Impulse-Measurement (HFIM).

Structure-borne sound signals of an actually cracked component are clearly distinguished in the 3D view (right) from noise and from other signals that are misinterpreted as cracks by conventional systems.

Characteristics of real cracks

Acoustic emission signals of real cracks are characterized by a extremely steep start, by extending into the highest frequency areas and by a smooth decline. These characteristics are only revealed by a analysis on three dimensions – time, amplitude and frequency.

Why change?

HFIM helps you to reduce false rejection rates, which means the components that are actually okay but in reality get rejected (wrongly).

Talk to us. Process optimization, tool and component monitoring and reduction of rejection rates are part of our core expertise. Get in contact with us to learn how much potential for savings is hidden in your processes!