This project is funded by the European Regional Development Funds (EFRE).

Optiform – Optimized online process monitoring to improve characteristics of a stamping process for high-strength steel during hot forming

Goal of the project: to gain information about the behaviour of components and raw materials during forming processes via acoustic emission (HFIM). This project startet April 1st, 2016 and will end March 31st, 2018. Partner of QASS: Institute for forming technology and light weight construction (IUL) at Technical University of Dortmund. This project is funded by european funds for regional development (EFRE NRW).

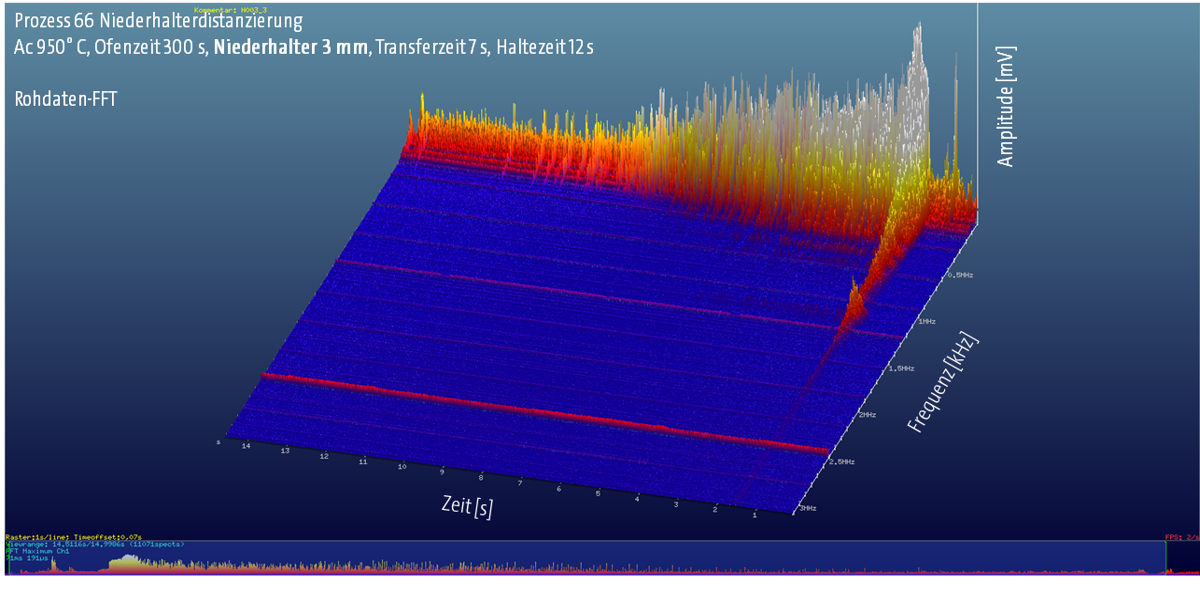

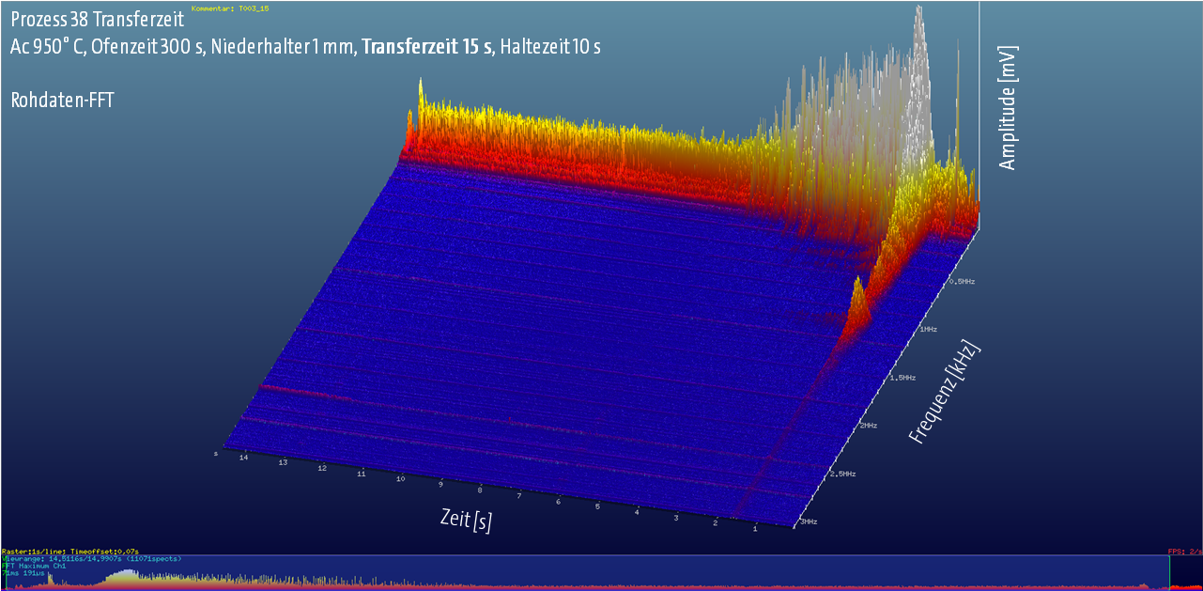

Acoustic emission waves, which are recorded in the form of solid-state sound waves by piezoceramic sensors directly on the mold, serve as the input variable for this project. This special method is called high-frequency impulse measurement (HFIM) and is based on the basic mathematical principles of envelope curve analysis. Spectra of the individual frequencies are generated by an FFT of the time-amplitude signals, resulting in a three-dimensional measurement result.

Statistical elaborations of the measured signals are carried out on the basis of temperature-controlled tensile tests and the pressing of demonstrators. In some cases, defects are deliberately introduced into the components in order to be able to observe their effect on the measured signals (cf. Figure 1). Databases are to be created in this way in order to be able to directly identify conspicuous features, for example cracks or deviating microstructural transformations, in direct comparison.

First results

The cognitive measurement system QASS Optimizer4D automatically detects the condition of a component. The images shown here are taken from a structure-borne sound measurement and show the HFIM signals of a defective and a perfect component.

HFIM-depiction of a forming process with a 1mm holding clamp. Result: component okay.

HFIM-depiction of a forming process with a 1mm holding clamp. Result: component okay.