New quality standards for crack detection in springs

Reliably detect cracks during production? QASS makes it possible.

Detect critical cracks during formation

During the forming process in spring coiling, damage can occur on the surface of the wire, leading to cracking. Springs have a critical influence on technical devices in various industrial applications and are therefore subject to high quality requirements. In collaboration with Wismar University of Applied Sciences, we have developed the first in-situ monitoring system for spring coiling, which detects cracking based on acoustic emissions (also known as structure-borne sound).

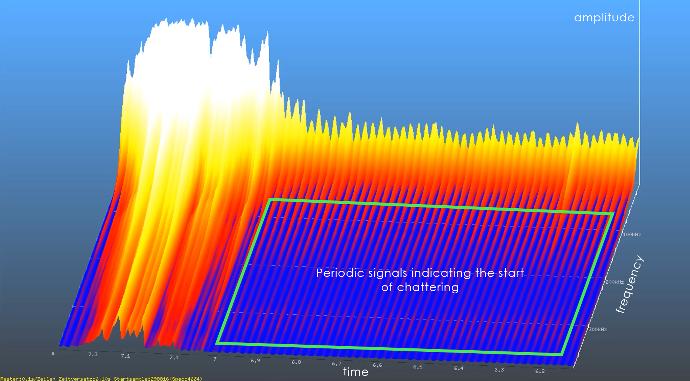

The Optimizer4D is a high-performance measurement device that can display sensor data in a real-time FFT landscape and features advanced analysis methods. Adaptive filter masks retouch noise, while intelligent pattern recognition searches for and evaluates known signal types. In this way, Optimizer4D enables early detection of potentially critical cracks..

Your contact person

Moritz Pollok

Sales

Phone: +49 02335/8020-16

Mail: mpollok@qass.net

Measurement method structure-borne sound

Important process signals can be recorded in real time using structure-borne sound analysis. Our measuring system can evaluate these signals and react accordingly to optimize your process.

Request

You contact us, by phone or by mail, and describe your situation

Target definition

We define the goals of the project together with you..

Data analysis

QASS measurement equipment is installed and collects data that is subsequently analyzed.

Application

The measurement technology is specially adapted to your purposes.

Evaluation

Our system is tested and optimized at your site under production conditions.

Arrange a consultation appointement now!

Ask our experts about the possibilities for your industrial processes without obligation.