Over a century of Barkhausen noise

The early 20th century is known for its discoveries and developments which are presently still relevant to us. They contribute to and improve our understanding of the world we live in. For instance, the discovery of subatomic building blocks took place in this period. Subatomic building blocks are the particles that form our universe. As their behaviour could no longer be explained using Newtonian physics, the theory of quantum mechanics was developed. Quantum mechanics define our knowledge of nature to this day.

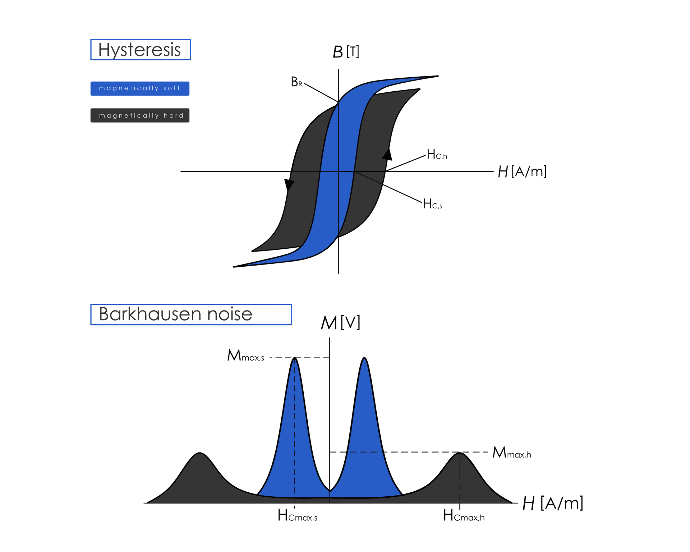

Another event in this era was the discovery of the Barkhausen effect Barkhausen noise is an effect which can only be observed in ferromagnetic materials. Ferromagnetism is a well-known form of magnetism commonly found in fridge magnets. In addition, there are more than half a dozen other forms of magnetism whose explanations are beyond the scope of this article. Ferromagnetic materials distinguish themselves from other materials by showing a hysteresis upon magnetization or alteration of the magnetic orientation. Hence, a hysteresis is the phenomenon exhibited by a ferromagnetic material, in which the reaction of the system to changes is dependent upon its past reactions to change.

Model of elementary magnets

To understand what happens in a ferromagnetic material when it is magnetized or when its magnetic orientation is changed, the models developed about 100 years ago need to be used. The French physicist Pierre-Ernest Weiss postulated the existence of elementary magnets in a ferromagnetic solid body. These elementary magnets, referred to as Weiss domains, have a certain magnetic direction. You could say that they represent the smallest magnetic areas in a material. Even though these magnetic areas are very small, they consist of many atoms. For the formation of Weiss domains, the crystallization of these atoms in a cubic space-centered lattice is necessary. Since ferromagnetism is a cooperative effect, it cannot be explained on the basis of individual atoms.

In einem nicht-magnetisierten ferromagnetischen Material zeigen die Elementarmagnete oder Weissschen Bezirke zufällig in alle Richtungen. Sie heben sich in ihren Wirkungen nach außen gegenseitig auf. Das Material verhält sich nicht magnetisch. Bringt man ein derartiges Material in ein äußeres Magnetfeld ein, richten sich die Weiss-Domänen parallel zu diesem aus bis das gesamte Material vollständig magnetisiert ist. Man spricht davon, dass das Material in der Sättigung ist. Das heißt, es kann nicht weiter magnetisiert werden. Und hier kommt die Hysterese ins Spiel: Wenn wir die Richtung des äußeren Magnetfeldes umkehren, beginnt das ferromagnetische Material damit, die magnetische Orientierung zu ändern. Dies geschieht zuerst langsam, da sich das effektiv wirksame Magnetfeld aus einer Überlagerung des äußeren sowie des inneren Magnetfeldes zusammensetzt. Diese beiden Magnetfelder sind einander entgegengesetzt, was dazu führt, dass zu Beginn nur ein abgeschwächtes äußeres Feld wirksam ist. Je weiter die Um-Magnetisierung fortschreitet, desto stärker wird das effektiv wirksame Feld. Hierdurch nimmt die Um-Magnetisierung an Geschwindigkeit zu, bis schließlich die magnetische Orientierung des ferromagnetischen Materials vollständig gewechselt hat. Wechselt man erneut die Orientierung des äußeren Magnetfeldes, wiederholt sich der Vorgang. Zuerst beginnt die Umorientierung langsam, dann nimmt sie Fahrt auf und geht schließlich in die Sättigung.

The emergence of hysteresis is logical and clear. Yet the curve has no continuous shape. It rather consists of small discrete jumps. Heinrich Georg Barkhausen proved experimentally that the reorientation of the individual elementary magnets does not take place simultaneously but successively and at random. Thereby, he confirmed Pierre-Ernest Weiss‘ assumption of the existence of elementary magnets. In his experimental setup, each change in the magnetic orientation of an elementary magnet caused a small current flow in a coil. This current can be made audible through an amplifier and loudspeakers, and sounds like as a series of crackling noises. Consequently, the effect is called Barkhausen noise.

Hardness testing with QASS µmagnetic – without contact and in a non-destructive manner

Although a hysteresis occurs in all ferromagnetic materials, its precise course is material specific. In particular, there are significant differences between hard magnetic and soft magnetic materials. This fact is utilized by the µmagnetic Messsystem . As hard magnetic materials are mechanically hard and soft magnetic materials are mechanically soft, one can use the QASS µmagnetic measuring system to determine the mechanical hardness value of a given material on the basis of its µmagnetic properties. Hardness testing can be carried out without contact, in a non-destructive manner, and potentially even in motion. This makes QASS µmagnetic the measuring system of choice for 100% hardness testing 24/7 in the production process.

- Advantages of the QASS µmagnetic measurement technology:

- QASS µmagnetic visualizes material properties at a glance

- Data evaluation is based on spectral analysis and adaptive frequency filtering

- A single measurement takes only a few seconds or less

- QASS µmagnetic works completely without touch and in a non-destructive manner

- Measurement results are displayed in real-time

- Nutzerfreundliche Visualisierung umfassender Auswertungen (Prozesslandschaft, Einzelwerte)

- QASS µmagnetic automatically recognizes any exceeding of tolerance limits

- Application possible pre-, in-, and post-process

- Easy integration into existing production chains

- Expandable with an individual handling system

- Attractive system solution including hard- and software

There is more to QASS µmagnetic than hardness testing

We are continuously refining our µmagnetic measuring system to make it even better. In addition to local hardness testing, our measuring system can also capture hardness curves. Hence, with QASS µmagnetic is also possible to detect lower hardness or re-hardening areas (e. g. due to grinding burn). Read more about this in the next blog post.

Kind regards,

Dr. Christian Radek