Geometrievermessung

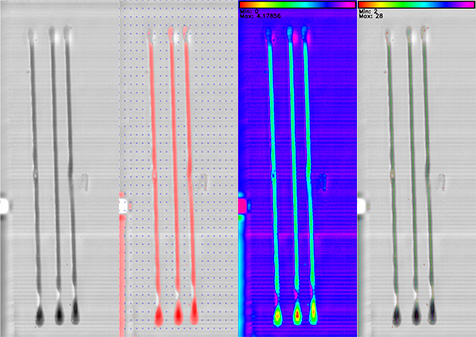

Präzise Geometrievermessung von Bauteilen zur Detektion von Oberflächenfehlern

Detektion von Oberflächenfehlern

Mit der QASS Geometrie Vermessung, scannen wir Ihre Bauteile und

integrieren diese als 3D-Daten in unsere Auswerteanalytik. Oberflächen-

und Baufehler werden so leicht sichtbar.

Individuelle Lösungen

QASS passt Lösungen und System ideal auf Ihren Prozess und Ihre

Anforderungen an. Benötigen Sie eine spezielle Softwareschnittstelle,

dann entwickeln wir diese. Benötigen Sie ein individuelles

Handlingsystem, dann richten wir den QOBOT perfekt für Sie ein.

Vielseitig einsetzbar

Die QASS Geometrie Vermessung ist vielseitig einsetzbar und kann durch

unser QOBOT Handlingsystem auch komplexe Geometrien präzise vermessen.

Pre-, In und Post-Process

Sämtliche Anwendungsmöglichkeiten von QASS sind sowohl vorgelagert,

in-process und nachgelagert am fertigen Bauteil möglich. Prüfen Sie Ihre

Objekte und Ihr Material zerstörungsfrei und berührungslos.

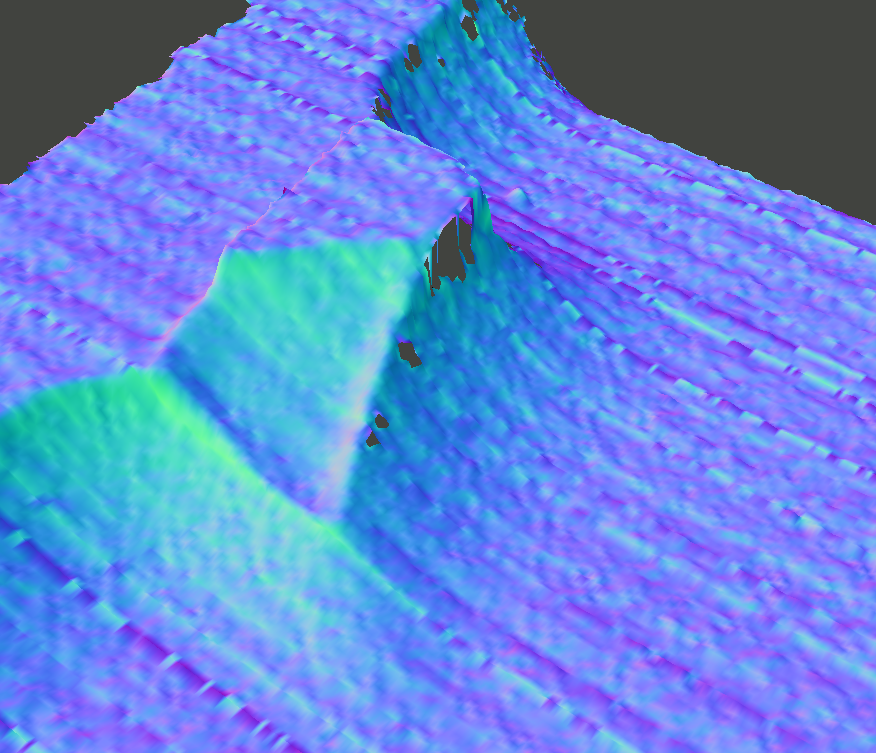

Geometrische Vermessung von Strukturen und Bauteilen

QASS hat verschiedene Geometriemesskonzepte in den Optimizer4D integriert. So können zusätzlich zur Akustischen-Datenaufnahme, nach belieben 3D Scans Ihrer Bauteile angefertigt und als 3D-Datenpunkte mit aufgenommen werden. Wir selbst nutzen diese Technik beispielsweise zur nachgelagerten Prüfung von Schweißnähten oder zur Detektion von Oberflächenfehlern. Mit den QASS-QOBOTS können die Sensoren flexibel in Fertigungsabläufe integriert oder direkt mit anderen QASS Messaufgaben kombiniert werden.

Alle Daten können auf integrierten Datenspeichern (z. B. 2-8 TB auf 2,5“ SSDs) gesichert werden. Alle Daten können in Echtzeit mit erprobten QASS-Methoden wie spektraler Energieauswertung, Mustererkennung oder Hüllflächenvergleich aber auch mit allen Python-basierten Analysemethoden ausgewertet werden.

Damit stehen auch verschiedenste Methoden des machine-learning zur Verfügung (z. B. Umwandlung der Höhendaten in Farb- oder Graustufenbilder und Verarbeitung z. B. mit OpenCV).

Details

- Hochauflösende Laserlinienscans (z.B. 2000 Messpunkte 2000 mal pro Sekunde) mit einer Abstandsauflösung bis zu 5µm

- Abstandspunktlaser (z.B. 2000 Messungen pro Sekunde) mit einer Abstandsauflösung bis zu 5µm

- TOF-Kamera

- Webcam

- Induktive Abstandssensoren

QOBOT Handling System

Das QOBOT Handlingsystem basiert auf einer intelligenten Kombination aus Sensorik und Robotik. Es wurde von QASS speziell für die µmagnetic-Technologie entwickelt und kann zusammen mit dieser als Systemlösung erworben werden.

Der QOBOT wird von QASS individuell auf den Prozess und die Fertigungsumgebung angepasst. Das System kann pre-, in- und post-process eingesetzt werden. Der im Handlingsystem verbaute kollaborierende Roboter ist flexibel einsetzbar und ermöglicht dank seiner Bewegungsreichweite von 924mm** eine Härtemessung von Bauteilen unterschiedlicher Geometrien und Längen. Ein Laserabstandssensor erfasst die Roboterbahn, sodass der µmagnetic-Sensor während der Messung korrekt positioniert wird. Die Steuerung der im QOBOT verbauten Sensorik und Robotik ist mit dem µmagnetic Messsystem integriert.

Zelos - Anlage zur Segmentdichteprüfung für Sinterteile

Die Zelos-Anlage wurde von QASS mit dem Ziel entwickelt, Unternehmen in der Qualitätssicherung beim Sintern zu unterstützen. Die Zelos-Anlage ist eine automatisierte Laboranlage zur Überprüfung der Verdichtung bei Sinterbauteilen. Das in der Anlage verbaute Messsystem ist der QASS Optimizer4D mit µmagnetic – der mikromagnetischen Erweiterung zur Härteprüfung, Schleifbrandprüfung und Segmentdichte-Prüfung für Sinterteile.

Die Zelos-Anlage zur Prüfung von Sinterteilen vereint die mikromagnetische Messtechnik mit einem schonenden Bauteil-Handling. Prüflinge werden mittels eines pneumatisch gesteuerten Magnetgreifers sanft aus der Halterung entnommen und über zwei Linearachsen zum mikromagnetischen Sensor geführt. Mit einem Laserabstandssensor wird die korrekte Positionierung des Prüfkörpers sichergestellt.

Jetzt Beratungstermin vereinbaren!

Informieren Sie sich unverbindlich bei unseren Experten über die Möglichkeiten für Ihre Industrieprozesse.