FAQ - Optimizer4D

Physikalische Grundlagen

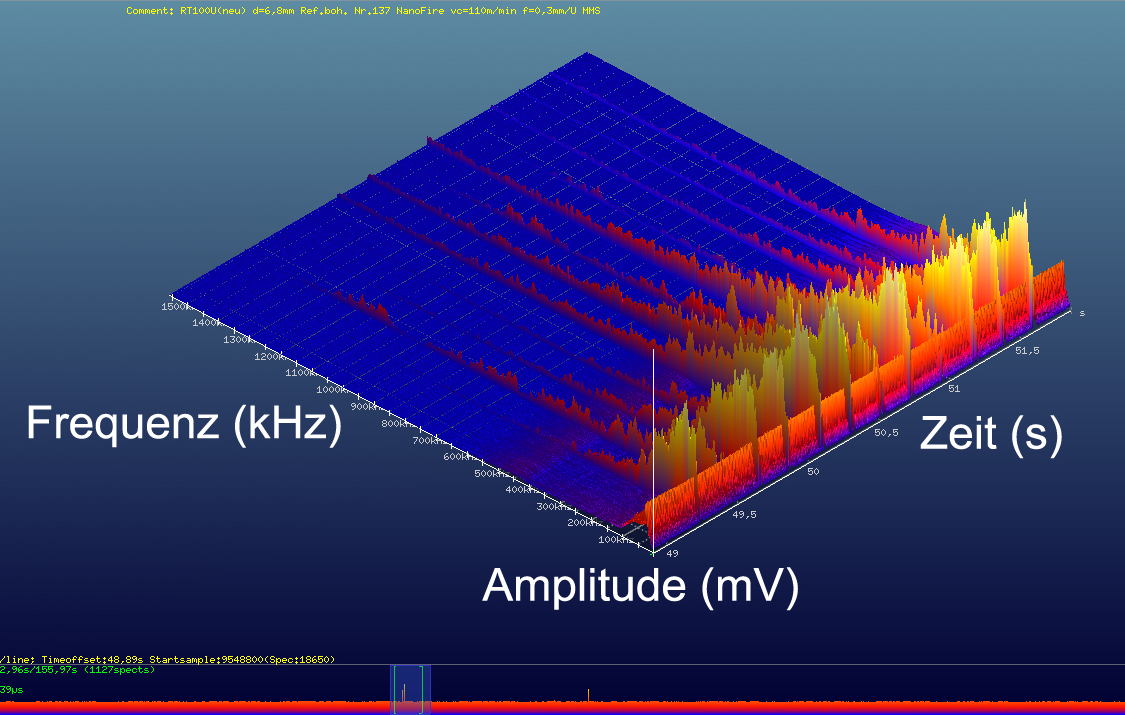

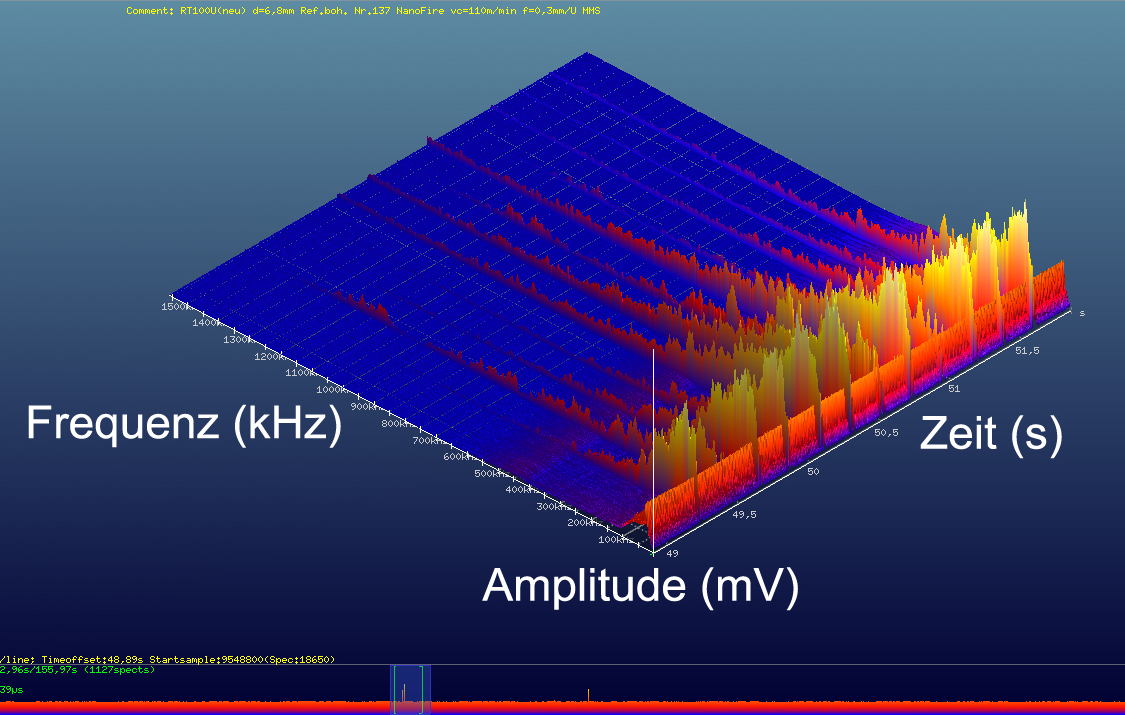

Prozessoptimierung und Risserkennung mit dem QASS Optimizer4D funktioniert auf der Grundlage der Analyse von Körperschall-Signalen. Der Optimizer4D bildet den Fertigungsprozess in einem dreidimensionalen Diagramm mit den Achsen Zeit (x), Frequenz (z) und Amplitude (y) ab. Das Messgerät muss auf den jeweiligen Fertigungsprozess eingerichtet werden. Risse sind aufgrund ihrer charakteristischen Form im dreidimensionalen Diagramm leicht und automatisch zu erkennen. Darüber hinaus ist die Qualifizierung anderer Prozessparameter möglich. Dafür ist es sinnvoll, das Messgerät auf den Soll-Zustand des Prozesses einzurichten. Abweichungen davon können später per Risserkennung oder Mustererkennung automatisch detektiert werden. Das Einrichten des Soll-Zustandes ist dafür Voraussetzung.

Dreidimensionale Darstellung der HFIM-Signale auf den Achsen Zeit (rechts), Frequenz (links) und Amplitude (vertikal).

Der Optimizer4D zeigt die gemessenen Hochfrequenz-Impuls-Messdaten in einem dreidimensionalen Diagramm an, auf den Achsen Zeit (x), Frequenz (z) und Amplitude (y). Die Differenzierung der Signale gelingt durch eine hochentwickelte Analysesoftware, die die Daten aus dem Körperschall-Sensor erfasst und unter anderem durch eine Fast-Fourier-Transformation aufbereitet. Durch diese Frequenztrennung werden die Signale der einzelnen Aggregate sichtbar und damit überprüfbar – zerstörungsfrei, automatisch und in Echtzeit. Dabei handelt es sich um einen höchst individuellen Vorgang, denn jede Produktionsmaschine und jeder Fertigungsprozess ist anders. Je feiner das Gefüge in Bauteil und Material, desto schneller folgen die Druckwellen aufeinander, und desto höher fallen die maximalen Schwingungsfrequenzen aus.

Achsenbeschriftung es Optimizer4D-Wasserfalldiagramms

Die Sensoren nutzen den piezoelektrischen Effekt. Durch Impulswellen

wird im Sensor eine Spannung erzeugt, die vom Optimizer gemessen wird.

Dieser Effekt lässt sich auch umkehren – wird der Sensor aufgeladen,

kann er einen Impuls aussenden. Um eine optimale Ankopplung und damit

eine optimale Auswertbarkeit der Körperschall-Signale gewährleisten zu

können, ist es ratsam, den Sensor an die Anlage zu schrauben

(M5-Gewinde). Je näher der Sensor an die Quelle der Impulse gebracht

wird, desto besser. Auch eine Ankopplung per Magnet ist möglich, die

Verschraubung liefert aber bessere Ergebnisse.

Riss-Signale äußern sich im dreidimensionalen Diagramm des Optimizers

stets durch ein breitbandiges, hochfrequentes Signal, das abrupt startet

und sanft ausläuft. Es ist typischerweise nicht an einen bestimmten

Frequenzbereich gebunden und unterscheidet sich von den

Arbeitsgeräuschen einer Maschine durch einen queren Verlauf zur

Zeitachse, durch einen scharfkantigen Beginn, durch seine Ausdehnung

über einen Großteil des Frequenzspektrums; vom hörbaren Bereich von

unter 20 kHz bis in die extrem hochfrequenten Bereiche von bis zu 1.5 MHz

und darüber hinaus. Die Dauer eines typischen Riss-Signals geht selten

über 20 ms hinaus.

Selten. In der Regel heben sich Riss-Signale deutlich von den üblichen

Arbeitsgeräuschen eines Fertigungsprozesses ab. Frequenzbereiche lassen

sich außerdem maskieren und aus den Messergebnissen rausfiltern. Im

Bereich der Werkzeugüberwachung kommt es darauf an, ob sich die Signale

des betreffenden Werkzeuges zeitlich oder räumlich von den

Arbeitsgeräuschen des Prozesses unterscheiden lassen, was in den

überwiegenden Fällen möglich ist. Eine Testmessung verschafft hier

Klarheit.

Echos und Resonanzen sind grundsätzlich Bestandteil einer

Körperschall-Messung und der Prozesscharakteristik. Entweder sie sind da

oder nicht – für die Messung und die Auswertung per HFIM spielt das

keine Rolle, denn so oder so ergibt sich ein typisches Abbild des

Prozesses.

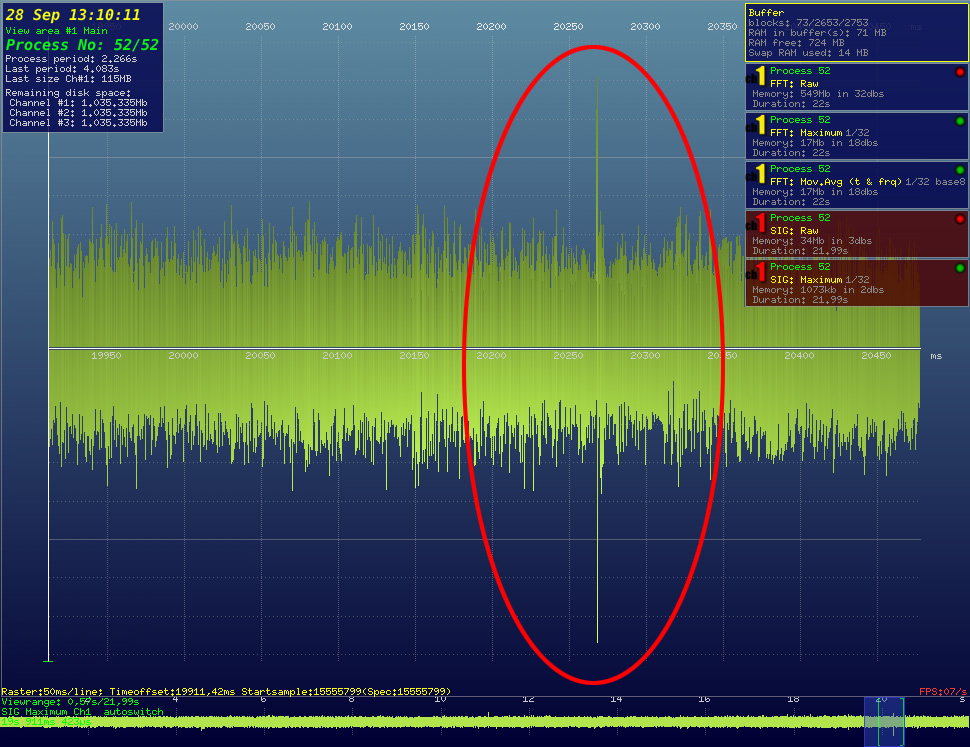

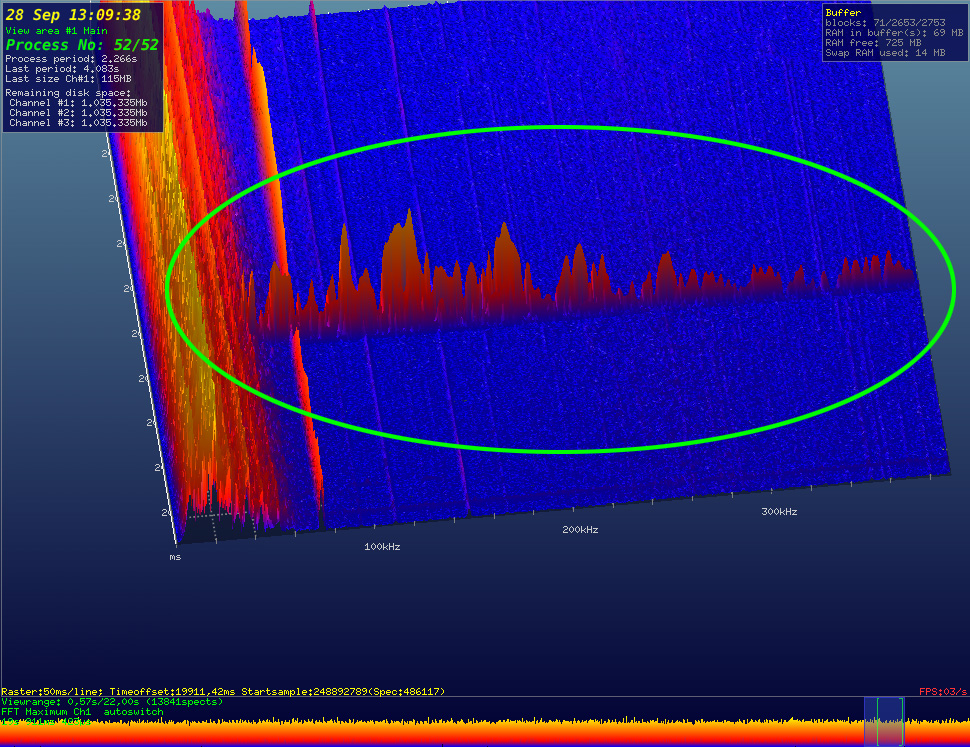

Herkömmliche Körperschallmessverfahren arbeiten in der Regel mit einer zweidimensionalen Darstellung von Zeit (x-Achse) und Amplitude (y-Achse). Optimizer4D misst zusätzlich den Frequenzbereich, beim Biegerichten zum Beispiel wird im vorgegebenen Bereich von 512 diskreten Frequenzen gemessen. Dieser Messbereich kann beliebig gefiltert und eingestellt werden, Hintergrund und Arbeitsgeräusche der Maschine lassen sich unterdrücken. Risse im Material zeichnen sich durch ein charakteristisches Signal aus und werden automatisch erkannt. Gleichzeitig ist es möglich, Muster zu erkennen.

Diese herkömmliche, zweidimensionale Darstellung von Körperschall-Signalen lässt kaum automatische Auswertungen zu. Der Signal-Stör-Abstand ist äußerst gering. Das markierte Signal eines Risses verschwindet vollständig im Rauschen.

Diese Abbildung zeigt dasselbe Signal wie die 2D-Abbildung. Der Unterschied: Der Optimizer4D stellt die

Körperschall-Signale auf drei statt auf zwei Achsen dar. Auffällig ist

vor allem die erheblich gesteigerte Trennschärfe, das markierte Signal

tritt klar und deutlich hervor. Eine automatische Risserkennung ist

einfach und sicher möglich.

Einsatzmöglichkeiten

Nein. Das Messgerät erkennt Risse und Prozessparameter nur in Echtzeit,

also in dem Moment, in dem sie entstehen. Ein Werkzeug oder Werkstück

kann also nicht nachträglich, nach der Bearbeitung, vermessen werden.

Dies gelingt nur während des Herstellungsprozesses.

Das ist unter Umständen möglich. Um Risse zuverlässig erkennen zu können, muss ein Körperschall-Sensor in den Prozess und kraftschlüssig zum Bauteil integriert sein. Die Verbindung zwischen Sensor und Bauteil ist Voraussetzung für den Betrieb des Optimizers. Je näher der Sensor zum Bauteil angebracht ist, desto besser können die Messergebnisse werden. Wird ein Bauteil an einer anderen Stelle angelassen als in der Induktionshärteanlage, die bereits durch den Optimizer überwacht wird, muss auch an der Anlass-Vorrichtung ein Sensor angebracht werden, möglichst nah am Bauteil. Je stärker der Sensor an das Bauteil oder an eine Haltevorrichtung angepresst wird, desto besser werden die Körperschall-Signale übertragen. Ob das schiere Gewicht eines Bauteils auf z. B. einer Trägerplatte (beim Abkühlen nach dem Anlassen) ausreicht, um Signale zuverlässig an einen Sensor weiterzugeben, der an der Platte angebracht ist, ist von vielen Faktoren abhängig. Gleichzeitig gilt es, Störgeräusche auf ein Minimum zu unterdrücken – gerade während der Abkühlphase fallen viele Störsignale auf, die unter Umständen mit den Signalen eines Risses verwechselt werden können.

Induktionshärtung

Es kommt darauf an. Häufig sind die Impulsemissionen von Flüssigkeiten

zu gering, um aus den weiteren Betriebsgeräuschen einer Anlage

zweifelsfrei identifizierbar zu sein. Es gibt aber auch Anlagen, in

denen z. B. der Fluss des Kühlmittels deutlich zutage tritt, etwa als

Frequenzband. Ist dies der Fall, lässt sich eine automatische

Überwachung realisieren. Grundsätzlich gilt aber, dass sich die

Messergebnisse immer verändern, sobald auch nur ein einziger Parameter

des Prozesses geändert wird – reißt zum Beispiel ein Schmierfilm ab, ist

dies deutlich zu sehen. Ähnliches gilt für den Ausfall der Kühlung.

Hier ist die einwandfreie Beantwortung allerdings schwierig und vom

Einzelfall abhängig.

Der Optimizer4D kann weitermessen. Für eine erfolgreiche Riss- oder

Werkzeugzustandserkennung ist es vorteilhaft, die veränderten Parameter

vor dem Arbeitsvorgang zu teachen und während des Prozesses per

Maschinensteuerung dem Optimizer4D mitzuteilen, bei Bedarf auf andere

Parameter zu reagieren. Riss-Signale unterscheiden sich deutlich von den

restlichen Arbeitsgeräuschen eines Prozesses. Der Optimizer4D kann

zusätzlich verschiedene Parameter eines Prozesses überwachen, z. B. ein

bestimmtes Frequenzband oder den Zustand eines bestimmten Werkzeuges,

und im Anschluss von sich aus mit der Produktionsmaschine kommunizieren,

um zu regeln, z. B. per SPS.

Viele verschiedene Kombinationen von Werkstücken, Materialien und Fertigungsprozessen lassen sich mit Optimizer4D überwachen. Das automatische Erkennen von Rissen ist allerdings auf eine exakte Parametrisierung auf Prozess und Werkstück angewiesen. Wechselt das Werkstück, ist es möglich, dass sich auch das Riss-Signal verändert. Jedes Werkstück muss aber nur einmal im Optimizer parametriert werden, das Messgerät kann buchstäblich Hunderte Werkstücke speichern – diese Liste von Risserkennungs-Parametern für Werkstücke ist nur durch den Speicherplatz der Datenbanken begrenzt. Es ist möglich, das Messgerät während des Herstellungsprozesses automatisch auf einen vorher definierten Parameter-Satz einzustellen, etwa durch die Steuerungstechnik SPS. Damit lassen sich wechselnde Werkstücke oder Prozessparameter überwachen – vorausgesetzt, sie wurden vor Beginn der Fertigung eingerichtet.

Grundsätzlich kann ein Optimizer4D nur eine Messung gleichzeitig

ausführen. Das Messsystem kann Signale aus bis zu 4 Datenkanälen

empfangen. Diese Kanäle können unabhängig voneinander ausgewertet und

zur Steuerung und Regelung herangezogen werden. Allerdings werden beim

Start der Messung alle Datenkanäle gleichzeitig gestartet. Stellt das

Gerät beispielsweise ein Riss-Signal auf einem der Kanäle fest, kann

dieser Kanal separat von den weiteren Datenkanälen ausgewertet werden –

etwa für die Steuerung und Regelung der Produktionsmaschine.

Voraussetzung für den Einsatz eines Optimizers an mehreren Maschinen

ist, dass die Maschinen gleich getaktet laufen – was den Start- und

End-Zeitpunkt einer Messung angeht.

Ja, es gibt verschiedene Gehäuse für den Optimizer, darunter auch verschiedene mobile Varianten (z. B. in einem tragbaren Koffer) oder in einem Umgehäuse (etwa für den Betrieb als Einzelgerät an einer Handrichtpresse). Eine Variante besteht aus dem widerstandsfähigem Transportkoffer QASE, im Lieferumfang enthalten ist ein Touchscreen-Monitor. Standard ist die Montage in einen Schaltschrank mit Anschluss an die Maschinensteuerung (z. B. SPS).

Eine Unterbrechungsfreie Stromversorgung ist Standard-Bestandteil des Optimizer4D. Die USV arbeitet mit Superkondensatoren („Supercaps“) und liefert ausreichend Energie, um das System nach einem Stromausfall herunterzufahren und auszuschalten, ohne Daten zu verlieren.

Das Gerät arbeitet standardmäßig mit einer eingebauten

Unterbrechungsfreien Stromversorgung (USV), und so sind bei einzelnen

Stromausfällen keine Probleme zu erwarten. Kommt es zu vielen An- und

Abschaltvorgängen, sind Datenfehler und Datenverluste möglich.

Testmessung

Die reine Dauer einer Prozessanalyse an einer Produktionsmaschine

beträgt mindestens drei Stunden. Hinzu kommt Arbeitszeit für die

Vorbereitung – Details der zu überwachenden Maschine müssen ausgetauscht

werden. Es ist notwendig, vor Beginn einer Prozessanalyse klare

Zielvorstellungen zu formulieren. Außerdem ist es hilfreich, wenn die

während der Prozessanalyse behandelten Werkstücke für eine zweite

Prüfung, etwa mit einer anderen Prüfmethode, zur Verfügung stehen. QASS

nimmt die Prozessanalyse mit Rücksicht auf den Herstellungsprozess vor;

gleichwohl muss immer eine gewisse Zeit für die Anpassung des

Messgerätes an den Fertigungsprozess einkalkuliert werden. Je besser die

Bedingungen, desto aussagekräftiger das Messergebnis. Die Unterstützung

durch einen erfahrenen Maschinenbediener während der Prozessanalyse ist

Voraussetzung.

Für eine Prozessanalyse sind Vorbereitungen nötig. In der Vergangenheit hat es sich als sinnvoll erwiesen, wenn QASS-Mitarbeiter sich auf die Maschine bzw. den Herstellungsprozess vorbereiten, der qualifiziert werden soll. Deshalb bitten wir vorab um so viele Informationen über Maschine und Prozess wie möglich. Im Kern geht es dabei immer um die Ankopplung der Körperschall-Sensoren bzw. der Sensoren. Diese müssen so nah wie möglich an die Stelle herangebracht werden, die überwacht werden soll – z. B. ein Werkzeug oder ein Werkstück.

Zur Vermeidung von Pseudo-Ausschuss ist es ratsam, die behandelten Werkstücke zu markieren, zu sammeln und unter Umständen einer nachträglichen Prüfung zu unterziehen (z. B. Magnetpulver), um die Signale des Optimizerskorrekt interpretieren zu können. Ist diese Interpretation einmal erfolgt, wird die nachträgliche Prüfung oft überflüssig.

Je mehr, desto aussagekräftiger wird das Ergebnis. Hier lässt sich keine

ausdrückliche Zahl nennen, es kommt auch auf den Fertigungsprozess und

auf die Werkstücke an. Die Erfahrung hat gezeigt, dass es von Vorteil

ist, eine gewisse Menge an Bauteilen für die Prozessanalyse zu

reservieren.

Messkette/Messempfindlichkeit

Sensor (optional: Keramikadapter zur elektrischen Entkopplung) – verschiedene Befestigungen (Verschraubung, Magnete) – Vorverstärker – Haupteinheit Optimizer4D – Mess- und Auswertesoftware Analyzer 4D.

Die Abtastrate beträgt 50 MHz, im Frequenz-Zeit-Signalstärke-Diagramm werden 25.000 Spektrallinien pro Sekunde in Echtzeit berechnet und dargestellt. Der Optimizer4D ist ein Messcomputer, der auf einem leistungsfähigen Linux-PC-System aufbaut und mit einer speziellen und maßgeschneiderten Messhardware ausgestattet wurde. Die Messhardware ist konstruiert für die Verarbeitung hochfrequenter Ultraschallsignale bis zu 25 MHz. Typischerweise erzeugt der Bruch einer Bleistiftmine in der Nähe des Sensors (der sogenannte „Nielsen-Test“ nach DIN EN 1330-9) einen klar erkennbaren Ausschlag mit der typischen Form eines Riss-Signals.

- 50 MHz Abtastrate für bis zu 4 Messkanäle

- Speicherung der Messdaten (bis zu 80 MB/s und Kanal) auf Festplatten (insgesamt bis zu 8 Terabyte Speicherplatz, reicht für bis zu ca. 11 Stunden Messung)

- 24V I/O-Einheit zur direkten Kommunikation mit der Maschineneinheit (ermöglicht automatische Prozessregelung)

- Umfangreiche Software mit zahlreichen Analyse- und Statistiktools

Das hängt auch mit den Arbeitsgeräuschen des Prozesses zusammen, die bei sehr kleinen Rissen und sehr breitbandig lauten Prozessen unter Umständen die Risserkennung erschweren können. Typischerweise gelingt bei guter Sensorankopplung der Nielsen-Test, bei dem eine 0,5mm starke Bleistiftmine am Bauteil zerbrochen wird – das Riss-Signal erscheint als deutlich erkennbarer Ausschlag mit der typischen Form (abrupter Beginn, hochfrequent und breitbandig) auf dem Bildschirm des Messgerätes. Voraussetzung dafür ist die kraftschlüssige Ankopplung des Sensors so nah wie möglich am Bauteil, möglichst ohne dämpfende Strukturen wie Lager oder Antriebe auf dem Weg zwischen Bauteil und Sensor.

Ein Riss in einem Werkstück, der vom Optimizer4D detektiert wurde.

Oft, aber nicht immer. Es kann aber vorkommen, dass sich ein

entstandener Riss im Werkstück an der Oberfläche schließt, noch während

der Bearbeitung. Dieser Riss ist dann zwar noch vorhanden an der

Oberfläche, aber nicht mehr sichtbar, da er zu weit geschlossen ist – er

entgeht der Prüfung per Magnetpulver oder Wirbelstrom. Optimizer4D ist

in der Lage, auch diese Risse zu erkennen – in dem Moment, in dem sie

entstehen.

Das Mess-System gibt ein Signal aus unmittelbar nach der Risserkennung

und noch während der Umformung, spätestens 100 ms nach Ende des

Messfensters.

Parametrisierung/Bedienung

Die Software vom Optimizer4D erlaubt die Unterscheidung gemessener Riss-Signale in Mikrorisse, Risse und Brüche. Alle drei Zustände sind frei parametrierbar. Grundlegend äußert sich die automatische Risserkennung von Optimizer4D durch ein frei definierbares Frequenzband in Kombination mit einem frei definierbaren Zeitraum. Zusätzlich kann ein Störpegel beschrieben werden, der es erlaubt, dass nur Energiewerte oberhalb des Schwellenwertes in die Energiebetrachtung, also in die Risserkennung, einbezogen werden. Die automatische Risserkennung kann durch externe Triggersignale, etwa per SPS-Maschinensteuerung, gestartet oder beendet werden.

Die Bezeichnungen Riss, Mikroriss und Bruch fungieren als Container für verschiedene Riss-Parametrisierungen, also für verschiedene Definitionssätze von Frequenzband, Zeitraum und Störpegel. Die Maschine kann von sich aus weder Risse noch Brüche erkennen; sie muss auf den jeweiligen Fertigungsprozess angepasst und eingestellt werden.

Messdaten von Prozessen werden gespeichert. Dies erlaubt es, die Messdaten immer wieder abzuspielen, gleich einer Film-Aufnahme, nur dass diese aus Körperschall-Signalen besteht. Die Riss-Parametrisierung lässt sich auf diese Aufnahmen anwenden und so lange anpassen, bis sie zuverlässig im gewünschten Parameterbereich anschlägt.

Das Messgerät zählt die Riss-, Mikroriss- und Bruch-Ereignisse und gibt bei Bedarf Warnungen auf dem Bildschirm oder per I/O-Ports aus, sollte die Zahl der Ereignisse einen vorher eingestellten Schwellenwert überschreitet.

Per Schnittstelle Optimizer4D-SPS. Zur Kommunikation mit der SPS stehen

im Optimizer4D 16 bis 24 Eingangssignale zur Verfügung, konfigurierbar

durch Softwareparameter. 8 bis 16 Ausgangssignale stehen im Optimizer4D

zu Verfügung, auch diese sind konfigurierbar über die Software. Auch

eine Anbindung an Profibus ist optional verfügbar.

Ja. Es gibt die Möglichkeit, die Messung für eine voreingestellte Dauer ablaufen zu lassen. Die Messung kann außerdem auch auf ein Signal aus dem I/O-Port oder auf eine Deaktivierung per Hand beendet werden. Es gibt eine weitere Möglichkeit, um etwas Ähnliches zu erreichen. Die Risserkennung kann für jeden einzelnen Kanal abgeschaltet werden, sodass die Messung zwar weiterläuft, die Risserkennung aber nur noch auf den noch eingeschalteten Kanälen läuft. Die Risserkennung kann per I/O-Port oder per Zeitlimit aktiviert oder deaktiviert werden.

Ja, für jeden Eingang können verschiedene Verzögerungen parametriert werden.

Optimale Prüfbedingungen bestehen, wenn die Maschine in Ruhe ist. Wenn

die Bewegungsgeräusche gering sind, sollte der Selbsttest auch während

der Bewegung funktionieren.

Einmalig: unter 100 ms, im Fehlerfall kann der Selbsttest wiederholt

werden, um die Messung abzusichern. Dadurch verlängert sich die

Testdauer entsprechend. Bei zwei Wiederholungen liegt die Dauer unter

300 ms. Mehr als zwei Wiederholungen haben sich in der Praxis als unnötig

erwiesen.

Ja. Eine Langzeit-Messung ist auch über Tage möglich. Dies ist

allerdings bei der Bestellung eines Gerätes zu berücksichtigen, da dann

der hierfür erforderliche Speicherplatz installiert werden muss.

Datenhaltung

Grundsätzlich werden verlustfreie Rohdaten in Echtzeit hinterlegt. Dieser Datensatz wird „Buffer“ genannt. Dieser Buffer kann später auf verschiedene Arten bearbeitet werden, um Störsignale auszublenden oder schwache Signale anzuheben. Standard ist die Bearbeitung mit Hilfe einer Fast-Fourier-Transformation, um die Darstellung auf den Achsen Zeit (x), Frequenz (z) und Amplitude (y) zu ermöglichen.

Diese Transformation arbeitet immer zerstörungsfrei und beeinflusst

die Originaldaten nicht. Die Messdaten werden in einem eigens

entwickelten Format auf dem Massenspeicher im Gerät abgelegt. Es ist

aber möglich, einzelne

Buffer im Dateiformat CSV (Character Separated Values) zu exportieren

und anschließend mit einem externen Tool zu bearbeiten (z.B. mit

Microsoft Excel).

Selbstverständlich. Das ist besonders komfortabel mit unserem Archivsystem. Preise und Lieferzeiten auf Anfrage.

Ja, Benutzer lassen sich in unterschiedliche Gruppen einteilen, die

unterschiedliche Zugangsberechtigungen erhalten. Fast jede

Einstellungsmöglichkeit, Funktion oder Parameter des Gerätes lassen sich

so individuell konfigurieren. Auf der einen Seite steht dann zum

Beispiel ein Maschinenbediener, der nur Informationen angezeigt bekommt

und keinerlei Einfluss auf das Gerät hat. Auf der anderen Seite steht

ein hoch autorisierter Anwender mit Zugang zu allen Feinheiten. Dieses

Benutzergruppen-System ist passwortgeschützt.

Grundsätzlich ist es möglich, die Rohdaten zu löschen und nur

komprimierte Daten zu erhalten. Diese sind allerdings naturgemäß weniger

genau als Rohdaten. Im Durchschnitt spart das Ausweichen auf

komprimierte Daten Festplattenkapazität um den Faktor 32.

Support/Service/Kaufabwicklung

Grundsätzlich handelt es sich bei Sensoren und Kabeln um Verschleißteile. Die Lebensdauer hängt sehr stark vom Einsatzgebiet ab. Prozesse, bei denen Sensor und Kabel regelmäßigen Bewegungen ausgesetzt sind oder anderen Einflüssen wie z.B. Kühlwasser, müssen früher ausgetauscht werden als Sensoren, die weniger Einflüssen ausgesetzt sind.

Wir gehen davon aus, dass Sensoren und Kabel länger als zwei Jahre

einwandfrei arbeiten. Im Zweifelsfall empfehlen wir, Verschleißmaterial

vorrätig zu halten. Außerdem wird die jährliche Kalibrierung des

Messgerätes nahe gelegt, allein, um es auf eventuell veränderte

Prozessparameter einzustellen.

Sie stellt sicher, dass das Messgerät einwandfrei arbeitet und auch das

misst, was es messen soll. Wir empfehlen, die Kalibrierung jährlich

vorzunehmen. Kunden werden rund drei Monate vor der Fälligkeit erinnert.

In Sachen Installation, Schulung, Prozessbegleitung und Reparatur gewährleisten wir allen Kunden weltweit unsere Leistungen. QASS ist so aufgebaut, dass der Hauptsitz in Deutschland (Wetter/Ruhr) weltweit alle Serviceeinsätze sicherstellt, entweder durch Techniker aus Deutschland oder durch unsere Vertriebspartner.

Ja, für telefonischen technischen Support stehen an unserem Hauptsitz in Wetter (Ruhr) wochentags zu den üblichen Geschäftszeiten kostenlos Techniker zur Verfügung. Diesen Service bieten wir auf Deutsch und auf Englisch. Wir können auch Support in den Sprachen Spanisch, Portugiesisch und Französisch anbieten.

Dringende Serviceeinsätze erledigt QASS so schnell wie möglich. Für

allgemeine Einsätze wie etwa eine Kalibrierung beträgt die Vorlaufzeit

bis zu vier Wochen.

In der Regel liegen QASS durch die jährlichen Kalibrierungen alle

Parametrisierungen und Kundeneinstellungen der Messgeräte vor. Das

bedeutet, dass ein kostenpflichtiges Ersatzgerät mit den entsprechenden

Parametern verschickt werden kann. Die Lieferzeit beträgt ohne Zoll in

der Regel weniger als 24 Stunden. Nach Erhalt des Ersatzgerätes ist das

defekte Gerät an QASS zu schicken. Im Zweifelsfall macht es sich

bezahlt, ein Ersatzgerät vorzuhalten.

Im Allgemeinen ist eine Remote-Unterstützung per Meshcentral möglich; dazu muss der Netzwerkzugriff über eine Standard-Ethernet-Verbindung konfiguriert werden. Der Optimizer muss eine Verbindung in das Internet erhalten. Dazu müssen Gateway- und DNS-Daten in Optimizer4D eingegeben werden. Ist Optimizer4D an das Internet angeschlossen, kann auf dem Optimizer der Firefox Internet-Browser ausgeführt werden (der bereits installiert ist). Team Viewer kann im Anschluss installiert werden (www.teamviewer.com; „Download rpm“; Details zu der Prozedur können Sie bei uns erfragen).

Es gibt allerdings andere, leichtere Möglichkeiten, um Remote-Unterstützung zu erhalten. Unserer Ansicht nach ist es die beste Lösung, dem Gerät ein sogenanntes Port Forwarding auf dem SSH Port (22) einzuräumen. In Einzelfällen ist auch eine drahtlose Anbindung möglich; hier haben wir gute Erfahrungen gemacht mit dem DLink DWR 512 Router.

Ja, und zwar in der Zeit von 8.30 bis 16.30 Uhr, montags bis freitags. In der Regel ist die Supportperiode bis ein Jahr nach dem Kauf eines Optimizers kostenlos. Über Support nach Abschluss dieser Periode muss einzeln verhandelt werden.

Sechs bis acht Wochen.

Preise sind auf Anfrage erhältlich unter info@qass.net oder per

telefonischer Anfrage unter +49 (02335) 80200. Die Zahlungsmodalitäten

werden individuell mit jedem Interessenten vereinbart und auf jeden

Kunden maßgeschneidert.

Ja. Die Kosten dafür berechnen sich je nach Einsatzgebiet und Aufwand

für die QASS-Techniker und werden jeweils individuell vereinbart.

QASS bietet zu Optimizer4D ein detailliertes Handbuch an; zusätzliches Material mit tiefergehenden Informationen wird während der Schulung angeboten. Nach Vereinbarung finden Seminare rund um Risserkennung und Prozessoptimierung mit Optimizer4D statt.

Ja. Ein Wartungsvertrag bringt in der Regel Preisvorteile mit sich beim

Blick auf die Reisekosten etwa für eine Kalibrierung. Je mehr

QASS-Kunden in einer Region liegen, desto mehr können die Reisekosten

für einen QASS-Techniker aufgeteilt werden.

Die Kabel gelten als Verschleißteile, und das Wartungsintervall richtet

sich nach der Arbeitsumgebung, in der die Kabel eingesetzt werden.

Sensoren sind Ersatzteile und sie müssen jährlich kalibriert werden.

QASS empfiehlt außerdem, die Festplatten alle zwei Jahre auszutauschen.

Kabel, Sensoren und Festplatten lassen sich als Ersatzteile einlagern

und vom Benutzer selbst auswechseln. Auf Wunsch wird ein Austausch auch

von QASS vorgenommen.

Ersatzteile wie Sensoren und Kabel sind stets verfügbar und können im

Notfall am gleichen Tag, an dem die Bestellung eingeht, verschickt

werden. Ist der Fall weniger dringend, werden Ersatzteile bis zu drei

Tage nach Eingang der Bestellung verschickt.

Die Garantiezeit beträgt ein Jahr und beginnt mit dem Tag der

Auslieferung. Sollte vor Ablauf dieses Jahres das Gerät kalibriert

werden, verlängert sich die Garantiezeit um ein Jahr. Die Gesamtzeit von

zwei Jahren kann nicht verlängert werden.

In der Regel wird das Gerät am Einsatzort kalibriert. Dies hat einige

Vorteile, zum einen ist es genauer, als das Gerät beim Hersteller zu

kalibrieren. Zum anderen können QASS-Techniker so gleichzeitig prüfen,

ob das Gerät noch ordnungsgemäß in den Prozess am Einsatzort eingebunden

ist. Alternativ ist es möglich, das Gerät zu QASS zu schicken – dann

muss allerdings die vollständige Messkette eingeschickt werden

(Messgerät, Kabel, Vorverstärker, Sensoren).

600 Euro plus Reisekosten.

Wir haben Ihr Interesse geweckt? Nehmen Sie jetzt Kontakt auf!

Wir freuen uns auf Ihre Anliegen und Fragen und helfen Ihnen gerne weiter