Körperschallmessung HFIM

So machen wir Ihre Prozesse messbar und sichtbar

Alleinstellungsmerkmal: Was kann nur QASS?

Herkömmliche Schallanalysegeräte untersuchen die Schwingungen eines Objektes. Optimizer4D geht den entscheidenden Schritt weiter und findet die Impulse, die die Schwingungen auslösen. Daraus ergibt sich ein Mehrwert für den Anwender: Ein industrieller Fertigungsprozess erzeugt viele Geräusche gleichzeitig, viele Körperschall-Signale. Diese überlagern sich zu Quietschen, Rattern usw. Optimizer4D ermittelt durch seine hohe Abtastrate, durch die Frequenzanalyse und durch die Musteranalyse die eigentlichen Quellen für jedes Geräusch.

Diese Auswertung basiert auf den Alleinstellungsmerkmalen von Optimizer4D:

- 50 Mio. Abtastungen pro Sekunde

- Spektralanalyse der Signale in Echtzeit

- Kognitiver Big-Data-Analyse, bestehend aus selektiven Frequenzfiltern, Mustererkennung und weiteren Software-Tools

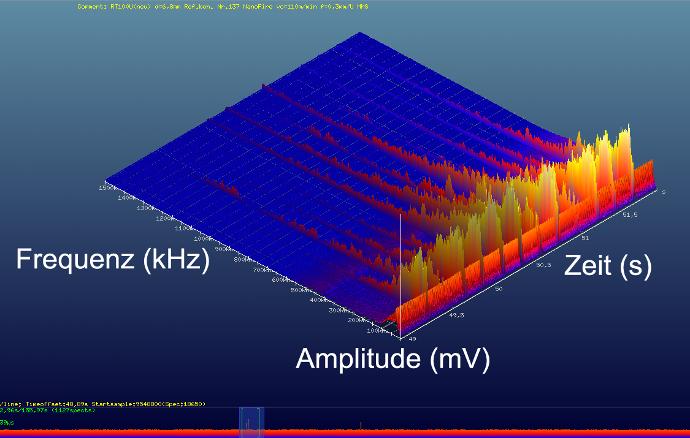

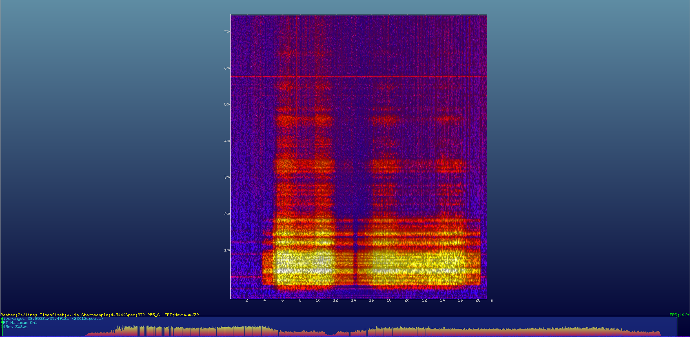

QASS Optimizer4D stellt die Körperschall-Signale dreidimensional dar – auf den Achsen Zeit, Frequenz und Amplitude. Verschiedene Vorgänge in Maschine und Bauteil zeigen so ihren ganz eigenen Fingerabdruck.

QASS Optimizer4D stellt die Körperschall-Signale dreidimensional dar – auf den Achsen Zeit, Frequenz und Amplitude. Verschiedene Vorgänge in Maschine und Bauteil zeigen so ihren ganz eigenen Fingerabdruck.

Der Weg des Signals

HFIM, Hoch-Frequenz-Impuls-Messung, besteht aus einer tiefgreifenden Analyse von Körperschall-Signalen. Maschine und Produkt emittieren Signale während der Bearbeitung.

Optimizer4D nimmt diese Signale mittels Piezo-Sensoren auf und wandelt sie per Fourier-Transformation in ein dreidimensionales Abbild des Prozesses um.

Kognitive Analyse-Algorithmen stellen den Zustand von Werkzeug, Maschine und Produkt fest – und liefern gegebenenfalls Steuer- und Regeldaten an die Maschine zurück (z. B. per Profibus/ IO-digital, Profinet u.w.).

Das Video zeigt eine einfache Demonstration der Funktionsweise von Optimizer4D: Ein Tischtennisball tickt auf und produziert so Körperschall. Optimizer4D von QASS nimmt diese Signale auf und stellt sie nach einer Spektralanalyse auf den Achsen Zeit, Frequenz und Amplitude dar. Live, in Echtzeit und zerstörungsfrei.

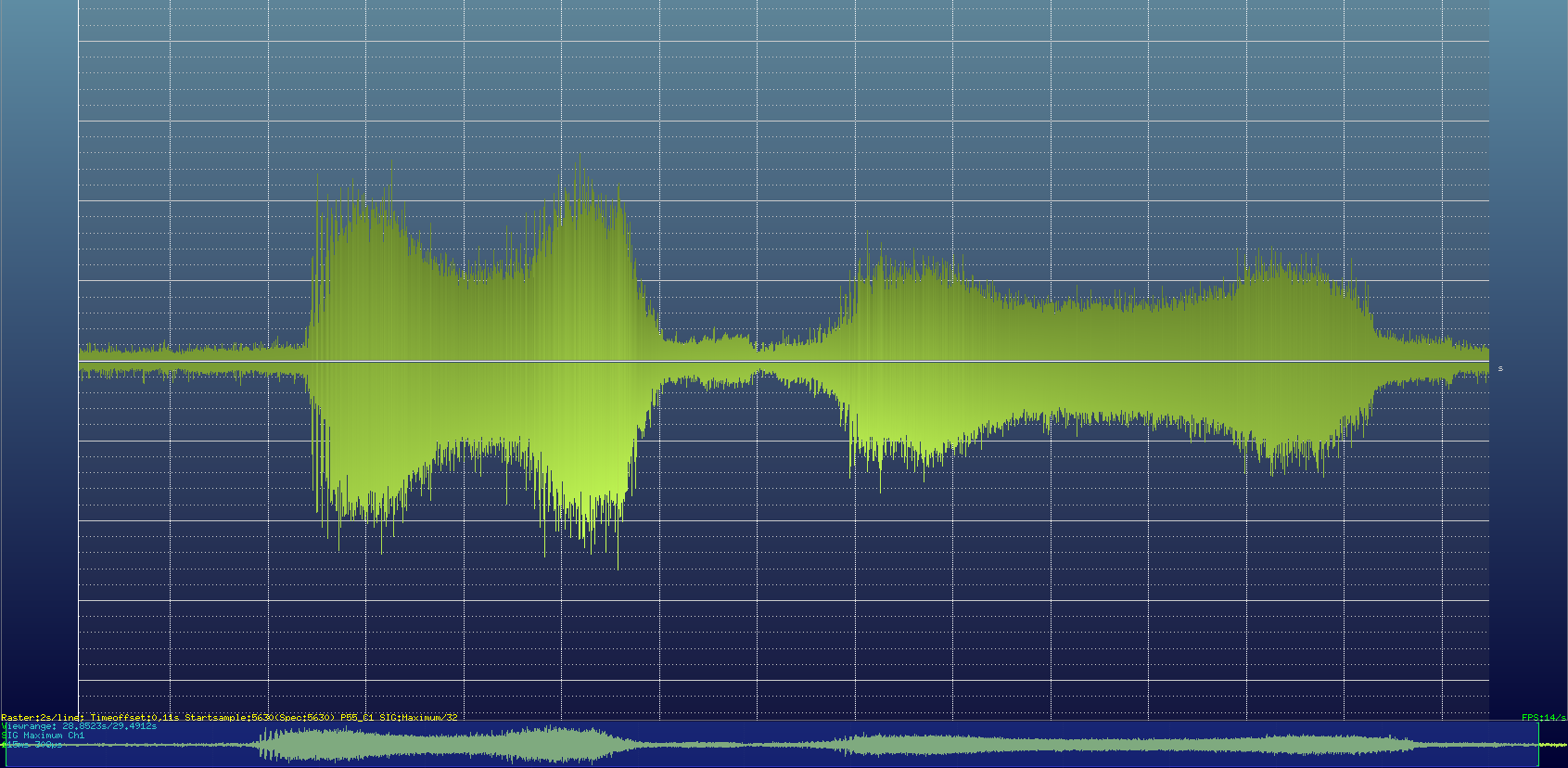

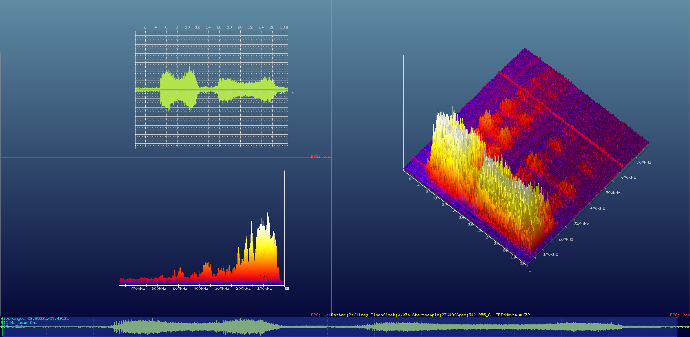

Körperschall-Signale in einem konventionellen zweidimensionalen Diagramm “Amplitude vs Zeit”.

Körperschall-Signale in einem konventionellen zweidimensionalen Diagramm “Amplitude vs Zeit”.

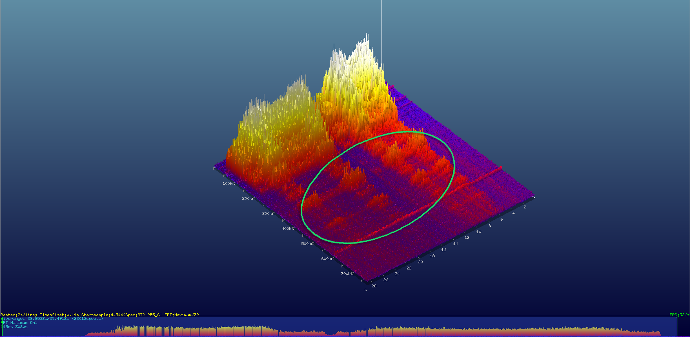

Dreidimensionales Körperschall-Abbild per Spektral-Analyse – die Quelle ist die gleiche wie im zweidimensionalen Abbild links.

Dreidimensionales Körperschall-Abbild per Spektral-Analyse – die Quelle ist die gleiche wie im zweidimensionalen Abbild links.

Die beiden Diagramme zeigen dasselbe Körperschall-Signal, einmal in einer konventionellen zweidimensionalen Darstellung, einmal in der dreidimensionalen Prozesslandschaft erzeugt durch die Spektral-Analyse. Deutlich wird das verbesserte Signal-Rausch-Verhältnis bei den hier auftretenden Signalen (grün markiert) hinter dem niederfrequenten Wellenberg. Die markierten Signale treten nur im dreidimensionalen Abbild zutage. In der zweidimensionalen Ansicht bleiben diese Signale versteckt.

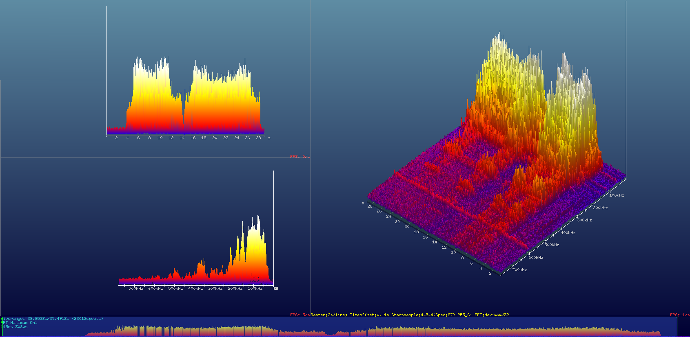

Blick auf das Diagramm auf den Achsen Zeit und Amplitude.

Blick auf das Diagramm auf den Achsen Zeit und Amplitude.

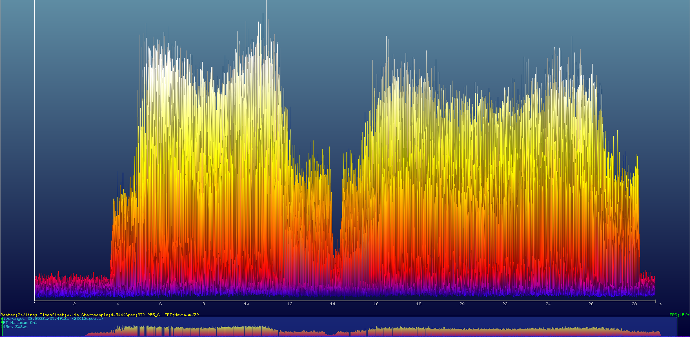

Blickwinkel auf die Achsen Zeit und Frequenz.

Blickwinkel auf die Achsen Zeit und Frequenz.

Mehrfach-Ansicht in Optimizer4D: Zeit vs. Amplitude (oben links); Frequenz vs. Amplitude (links unten); Zeit vs. Frequenz vs. Amplitude (rechts).

Mehrfach-Ansicht in Optimizer4D: Zeit vs. Amplitude (oben links); Frequenz vs. Amplitude (links unten); Zeit vs. Frequenz vs. Amplitude (rechts).

Das gleiche Signal in drei verschiedenen Darstellungsformen – nur Optimizer4D von QASS beherrscht diese Spektralanalyse von Körperschall-Signalen.

Das gleiche Signal in drei verschiedenen Darstellungsformen – nur Optimizer4D von QASS beherrscht diese Spektralanalyse von Körperschall-Signalen.

Details

Die vierte industrielle Revolution, meist verbunden mit Schlagwörtern wie „Smart Factory“ oder „Internet der Dinge“, stellt eine ganze Bandbreite an Herausforderungen an moderne Produktionsanlagen.

Einerseits wird eine Fülle von Daten aus der Produktion direkt verfügbar gemacht und eröffnet somit das Potenzial für schnellere, bessere und günstigere Produktionsprozesse. Andererseits benötigen diese Datenmengen völlig neue Auswertealgorithmen und Handlingstrategien, um dieses Potential voll zu entfalten. Es ist demnach keinesfalls ausreichend, Daten nur zu messen und abzuspeichern.

Kognitive Messtechnik

Die eigentliche Herausforderung beginnt erst danach – sie liegt in der Aufbereitung und Interpretation dieser Datenmengen, um nützliche Informationen zu gewinnen und konkrete Entscheidungen zu treffen. Das ist, was QASS „Kognitive Messtechnik“ nennt: aussagekräftige Interpretation von Messdaten, noch während diese erhoben bzw. gemessen werden.

Die Technologie, um diese herausfordernde Aufgabe zu meistern, ist die patentierte Hoch-Frequenz-Impuls-Messung, kurz HFIM. Dabei handelt es sich um ein spezielles Verfahren der Körperschall-Analyse. Hierbei wird während des Messvorgangs eine Frequenzanalyse, meist mittels der Fast-Fourier-Transformation, der aufgenommenen Schallamplituden durchgeführt. So werden in Echtzeit, nicht nur Informationen über die Lautstärke des vermessenen Vorgangs gewonnen, sondern auch deren Frequenzverteilung.

Einfache Unterscheidung zwischen Störung und Signal

Dies ermöglicht die einfache Unterscheidung zwischen Störsignalen (z. B. Maschinengeräusche) und prozessrelevanten Signalen (wie Rissbildungen oder Verschleiß), selbst wenn diese deutlich schwächer ausgeprägt sind als die Störgeräusche. In-Line-Qualitätsüberwachung, Predictive Maintenance und Prozessdokumentation – die HFIM-Technologie ist für eine vielfältige Palette an industriellen Fertigungsprozessen verfügbar.