Non-Destructive Hardness Testing

Non-destructive hardness measurement, automated and reliable with the QASS measuring system

Non-destructive, contactless and in real time

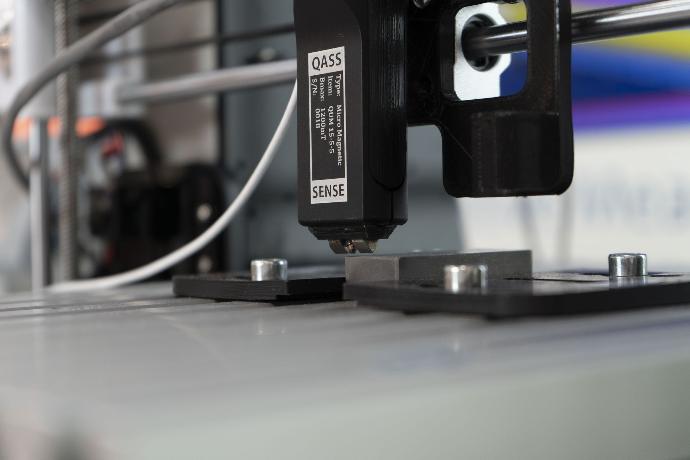

With our µmagnetic measuring system, you can test the hardness of ferromagnetic materials in a non-contact and non-destructive manner. Real-time spectral analysis makes the properties of your material visible live. Components can be measured within 200 ms.

Customer and process specific solutions

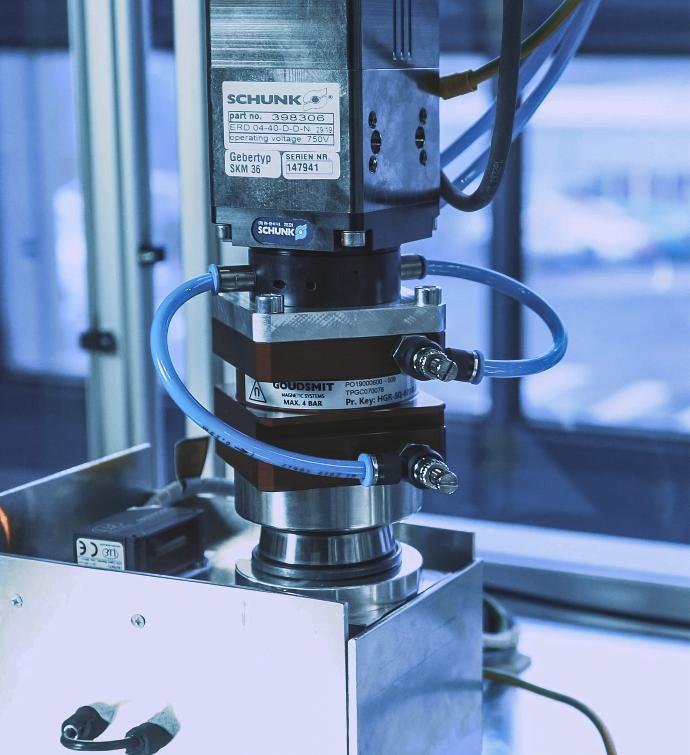

QASS adapts the µmagnetic measuring system to fit your process and non- destructive hardness testing requirements ideally. If you need a special sensor design, we will develop it. If you need an individual handling system, we will set up the QOBOT perfectly for you.

100% instead of random testing

Our µmagnetic technology can be integrated into all process stages of manufacturing. Be it material or mix-up tests before the first manufacturing step or quality tests in or at the end of the manufacturing process.

Hardness testing Pre-, In- and Post-Process

All applications of QASS µmagnetic are possible upstream, in-process and downstream of the finished component. Inspect your objects and material non-destructively and contact-free. The implementation in the process depends on the available space and the process control.

Micromagnetic Hardness Testing

To determine the hardness, the material to be measured is exposed to an alternating magnetic field and the reorientation of the individual magnetic domains in the microstructure of the material is measured. The time-amplitude signal recorded by the micromagnetic sensor is digitized by the QASS µmagnetic measuring system and processed by a Fast Fourier Transformation (FFT) in real time to reveal the frequency components (pitches) hidden in the signal. The method used by QASS for spectral analysis is called High Frequency Pulse Measurement (HFIM). Within the scope of the spectral analysis, machine noise and interference noise, as well as electromagnetic interference, can be specifically filtered out of the signal data by means of a spectral filter (also called frequency mask). This improves the relationship between useful and interfering signals. Additionally, continuous endless measurement of materials is possible, such as in the production of strip steel, for example.

Flexible Range of Application

Cycle times in the order of seconds can easily be realized with the system.This is because hardness measurement with the QASS µmagnetic system usually takes less than one second. A hardness measurement consists of several individual measurements of the reorientation of the magnetic domains inside the material.

In addition to static measurements, our µmagnetic system allows measurements in motion. This allows the recording of hardness profiles, for example to assess the quality of weld seams or to examine tooth flanks for grinding burns. Since the measurement is contactless, contamination (oil, scale, etc.) or oxidation of the surface is irrelevant. The measurement in motion can be realized by QASS with the QOBOT handling system.

Micromagnetic as System Solution

Handling systems & complete solutions

Arrange a consultation appointment now!

Ask our experts about the possibilities for your industrial processes without obligation.