Test benches

Precisely determine application limits of processes in test benches

Process optimization through sensor technology in test stands

Test rigs are used to simulate load situations of industrial applications. Different parameters can be added or taken away from the test in order to reproduce the load collective of the field application gradually. This identifies the loads that have a significant influence on the service life of components or materials. The intensive use of various measurement techniques helps to determine the times of component or material reactions, which then better determine the limits of use.

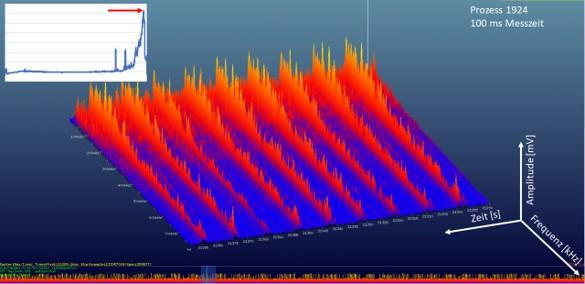

Measurement method structure-borne sound

Using structure-borne sound analysis, important process signals can be captured in real time. Our measurement system can evaluate these signals and react accordingly to optimize your process.

Application examples

The QASS measurement technology is applicable in many areas. We focus on the individual requirements of the customer and also carry out research projects.

FLC Test

The FLC test is used to determine forming limit curves of sheet materials are determined with the aid of a defined forming process. This allows optimization of forming tools and component geometries.

The failure criterion is the generated crack. The detection of the flow behavior and crack formation takes place using an optical image correlation method. For this purpose, a speckle pattern is applied to the samples using paint and chalk spray, and cameras and algorithms are used to determine the changing distances between points of the speckle pattern during the test. Using structure-borne sound detection, QASS has investigated crack initiation and found that the stiffness of the applied speckle pattern makes crack detection with optical image correlation more difficult and the crack in the sheet material occurs much earlier. Our measurement system thus provides more accurate failure times than previously applied systems.

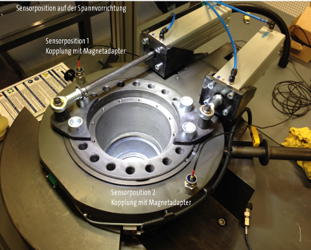

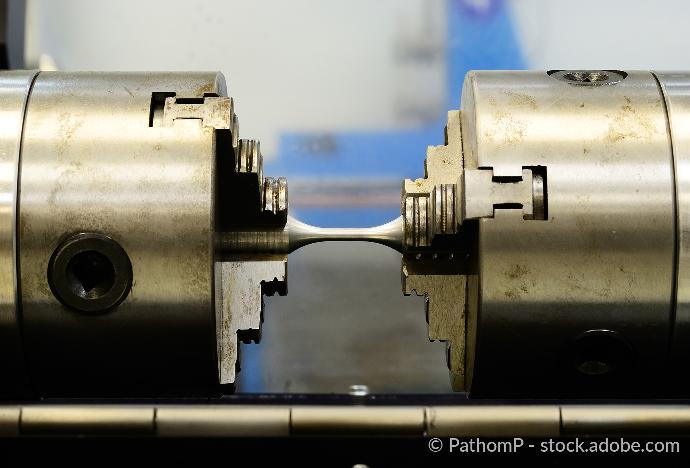

Torsion test stands

Components that have to withstand torsional loads are frequently subjected frequently subjected to overload tests in torsion test rigs. The components are clamped and twisted against each other. If a crack occurs in the process, the components are sorted out. QASS can draw on it's experience in

crack detection from many other projects in this context. Crack detection is strength of QASS, as it detects the structure-borne sound waves triggered during crack initiation are detected using piezoelectric sensors.

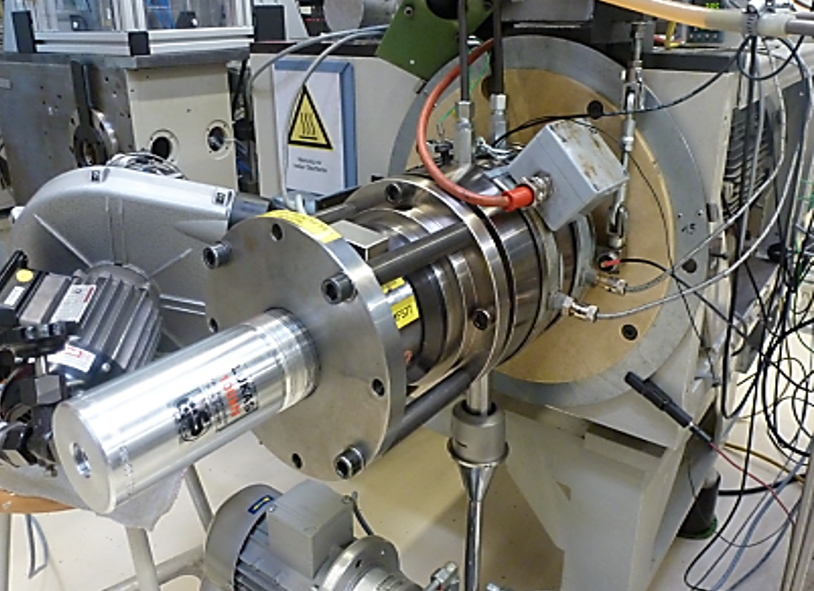

Bearing test stands / Friction test stands

Structure-borne sound analysis is ideally suited to detect tribological mechanisms. QASS was first able to detect the phenomenon in machining on worn tools and was first transferred to FE-8 test rigs in 2011. FE-8 test rigs are used to evaluate the wear of standardized bearings in combination with different lubricants and asses the suitability for specific applications. In-situ tests can be carried out to determine how additives affect friction behavior. The method can now be scaled to different system sizes and is used in large bearing test rigs, among other applications. One main success is the detection of early damage caused by white-etching cracks (WEC).

The QASS project workflow

Request

You contact us, by phone or by mail, and decribe your situation.

Target definition

We define the goals of the project together with you.

Data analysis

QASS measurement equipment is installed and collects data that is subsequently analyzed.

Application

The measurement technology is specially adapted to your purposes.

Evaluation

Our system is tested and optimized at your site under prodution conditions

Arrange a consultation appointment now!

Ask our experts about the possibilities for your industrial processes without obligation.