Intelligente Messtechnik

QASS Messsysteme bleiben kontinuierlich auf dem neuesten Stand der Technik und erweitern täglich ihr Repertoire. Die Nutzung von fortschrittlichen Technologien wie Mustererkennung, Clustering-Algorithmen und Deep Learning ist für QASS selbstverständlich und integraler Bestandteil unserer Arbeitsweise.

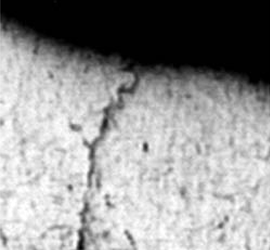

Risserkennung beim Biegerichten

Wir sind Weltmarktführer in der Risserkennung. Unser Messsystem "Optimizer4D" ist mit einem innovativen Analysekonzept ausgestattet, das den Pseudo-Ausschuss reduziert und durch die Analyse von Intensität, Energieverlauf und Frequenz jedes Detail des Richtvorgangs enthüllt.

Rattermarkenerkennung beim Rohrzug

Der QASS Optimizer4D kann Vibrationen frühzeitig erkennen, um anschließend die Ziehgeschwindigkeit der Maschine zu reduzieren. So können Rattermarken und damit verbundene Produktionsfehler vermieden werden.

Härteprüfung von Werkstoffen

Mit unserem µmagnetic Messsystem prüfen Sie die Härte von ferromagnetischen Werkstoffen berührungslos und zerstörungsfrei. Durch die Echtzeit-Spektralanalyse werden die Eigenschaften Ihres Materials live sichtbar und in Echtzeit ausgewertet.

Der QASS Machine Learning Baukasten

ideal präpariert für Forschung, Entwicklung

und den industriellen Einsatz

- Der Mess-Cube „Optimizer4D“, ein kompakter Hochleistungs-PC mit Linux als offenem Betriebssystem, und allem was man für industrietaugliche machine-learning Implementierungen braucht.

- QASS Körperschallsensoren können aus nahezu jedem Fertigungsprozess Big-Data gewinnen und für die Prozessanalyse und Optimierung nutzen.

- Offene Kommunikationsmodule zur Integration aller denkbaren Datenquellen und Korrelation mit Hochgeschwindigkeits-Messdaten.

- QASS Open-Source Module integrieren den „Optimizer4D“ ins Netzwerk und in machine-learning Entwicklungs-Umgebungen wie Jupiter Lab.

Aktuelles

Die Revolution der industriellen Messtechnik

QASS ist der Spezialist für Bauteilüberwachung, Prozessoptimierung, Risserkennung und Tool Monitoring. Als Weltmarktführer in der Risserkennung beim Richten von Stahlwellen hat unser neues Verfahren Hoch-Frequenz-Impuls-Messung (HFIM) neue Maßstäbe gesetzt.

Kognitive Sensorik ist interpretierendes

Messen

–

Optimizer4D erkennt selbsttätig und in Echtzeit, wenn ein

Produktionsprozess Toleranzgrenzen überschreitet. QASS-Systeme

analysieren große Mengen an Sensordaten in Echtzeit und erkennen darin

verborgene Muster. Die Kombination von kognitiver Messtechnik und

hochfrequentem Körperschall ermöglicht eine neue Dimension der

Prozessdatenanalyse. Wo früher nur Rauschen messbar war, können nun

Erkenntnisse gewonnen werden, die den Zustand eines

Bearbeitungsvorganges qualitativ beschreiben. Maschinen können so selbst

beurteilen, ob der letzte Bearbeitungsschritt erfolgreich war.

Qualitätssicherung

100% Bauteilüberwachung - inklusive lückenloser Dokumentation.

Tool Monitoring

Zustandsprüfung von Werkzeug und Maschine.

Risserkennung

In-process und zerstörungsfreie Rissprüfung beim Richten von Bauteilen.

Prozessoptimierung

Senkung des Ausschusses und Optimierung von Wartungsintervallen.

So einfach geht's

So einfach geht's

Anfrage

Sie nehmen mit uns, telefonisch oder per Mail, Kontakt auf und schildern uns Ihre Situation.

Zieldefinition

Wir definieren gemeinsam mit Ihnen die Ziele des Projekts.

Datenanalyse

Die QASS Messtechnik wird installiert und erfasst Daten, die im Anschluss analysiert werden.

Applikation

Die Messtechnik wird speziell auf Ihre Zwecke angepasst.

Evaluation

Unser System wird bei Ihnen unter Produktionsbedingungen getestet und optimiert.

Jetzt Beratungstermin vereinbaren!

Informieren Sie sich unverbindlich bei unseren Experten über die Möglichkeiten für Ihre Industrieprozesse.